Motor driver ru

Inhaltsverzeichnis

Описание

Ardumower's design uses two different types of motors (all motors can be purchased via the shop ![]() ):

):

- Two motors (with integrated gearing) for driving (wheel motors), and encoder (for distance, direction and speed control)

- One motor (with high rotation speed) for mowing (mower motor)

To control a motor, it requires a 'motor driver'.

Voltages

Although there exist 12V motors and 24V motors, as in all modern systems, the Ardumower uses 24V motors. The reason is as follows:

Assuming that the motor consumes 50W, using 24V results to a motor current: 50W / 24V = 2A.

Assuming that the motor consumes 50W, using 12V results to a motor current: 50W / 12V = 4A.

The higher the current (A), the more problems arise:

- The motor driver must be suitable for higher current (more expensive)

- The PCB traces need to be more thick (more expensive)

- The rechargable battery need to support higher current (more expensive)

So, that's the reason why Ardumower is designed as a 24V system.

Wheel motors

The two left and right gear motors are controlled independently (aka 'differential driving') to:

- drive the robot forward/backward

- steer the robot left/right

The Ardumower wheel motor features:

- A rotation speed up to 31 rpm allows to move the robot at sufficient speed (at up to meter/sec = 31rpm/60 * PI * 0.25m = 0.4m/sec using 250mm diameter wheels)

- A high torque (2.45Nm) guarantees that the robot can climb small hills as well (with 2 motors, 0.125 radius wheel, 31rpm = 0.4m/s, acceleration = 0.2 ( 1/2 of nomeinal speed) up to 14 degree) see calculator

- Integrated encoders, so it can measure the rotation speed, the distance and the direction (see Odometry for more information) - Encoders are REQUIRED for Ardumower software.

- 24V (load current ~1A)

Motor driver

A motor driver is a circuit that allows current to flow either one direction or the opposite direction through the motor - depending on wether the motor should turn forward or backward (so called 'H-bridge'). There are many motor drivers available as ready-circuit boards, some can even control two motors (Dual H-Bridge) - if you connect two of their H-bridges in parallel, the maximum motor current can be increased.

If the direction of the motor does not need to be controlled, (e.g. for the blades), you do not need an H-bridge, but instead a simple 'switch' (e.g. MOSFET-transistor-circuit).

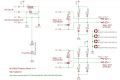

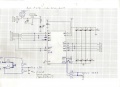

The motor driver is connected through control signals to the Arduino. Example:

Arduino Digital Pin —> MOTOR-Direction Pin (DIR) Arduino PWM Pin —> MOTOR-Speed Pin (PWM) Arduino Analog Pin <— MOTOR-Current Sensor Pin

One pin controls the direction (forward/backward), the other pin controls the speed. One analog input pin is connected to the current sensor. The current sensor module (ACS712-05A) is connected in series with the motor.

NOTE: only for demonstration! See real schematics for concrete wiring

PWM frequency

The speed of the motor is controlled by a PWM duty signal. We use the Arduino default PWM frequency (490 Hz) to control the motor drivers.

Popular modules

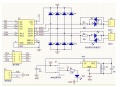

MC33926 (recommended)

Особенности: up to 3A with integrated current sensor and thermal shut-down protection, for all kind of robot mowers)

M1_FB --- pinMotorLeftSense A1 M1_SF --- pinMotorLeftFault 25 M1_PWM_D1 --- connect with jumper to GND M1_PWM_D2 --- connect with jumper to VDD M1_IN1 --- pinMotorLeftPWM 5 M1_IN2 --- pinMotorLeftDir 31 EN --- pinMotorEnable 37 M2_FB --- pinMotorRightSense A0 M2_SF --- pinMotorRightFault 27 M2_PWM_D1 --- connect with jumper to GND M2_PWM_D2 --- connect with jumper to VDD M2_IN1 --- pinMotorRightPWM 3 M2_IN2 --- pinMotorRightDir 33 EN --- pinMotorEnable 37 VDD --- Arduino 5V

IBT-2 (BTS7960/BTN7960)

Особенности: 5.5-27V, 43A (цена 9 USD)

На один двигатель требуется один модуль.

Pinout:

1 RPWM Forward level or PWM signal input, active HIGH 2 LPWM Reverse level or PWM signal input, active HIGH 3 R_EN Forward drive enable input, HIGH enable, LOW Close 4 L_EN Reverse drive enable input, HIGH enable, LOW Close 5 R_IS Forward drive - side current alarm output 6 L_IS Reverse drive - side current alarm output 7 VCC 5V power input from Arduino board. 8 GND Ground.

пример подключения 1 пример подключения 2 смотри комментарий 11

BTS7960B GND --- GND BTS7960B VCC --- Arduino 5V BTS7960B R_IS --- нет BTS7960B L_IS --- нет BTS7960B R_EN --- Arduino MOTOR_DIR pinMotorRightDir 33 BTS7960B L_EN --- Arduino MOTOR_DIR pinMotorLeftDir 31 BTS7960B R_PWM --- Arduino MOTOR_PWM pinMotorRightPWM 3 BTS7960B L_PWM --- Arduino MOTOR_PWM pinMotorLeftPWM 5 BTS7960B MOTOR(+) --- motor(+) BTS7960B MOTOR(-) --- motor(-) BTS7960B POWER(+) --- battery(+) BTS7960B POWER(-) --- battery(-)

L6201P

Особенности: 48V, 4A

B+ power supply output voltage equal to the power connector GND GND EN driver enable RPWM forward PWM signal, active HIGH LPWM reverse PWM signal, active HIGH CT current signal output VT voltage signal output

Forward EN=1, RPWM=PWM, LPWM=0 Reverse EN=1, RPWM=0, LPWM=PWM (also possible? EN=1, RPWM=255-PWM, LPWM=1 => needs to be verified!) Brake EN=1, RPWM=0, LPWM=0 Not brake EN=0, RPWM=x, LPWM=x Note: 1=High level (3.3-5v), 0=Low level (0V or GND)

L9958

Особенности: Arduino 240W H-bridge Motor Driver Board - SX8847, up to 8A

Note that this module has an on-board linear voltage regulator, which converts the input POWER (typically 24 or 12V) to 5V. Some modules do this with a single voltage regulator (chip VR1 on the module), or in a two-staged approach (VR1 and U2).

Converting 24V to 5V with a linear voltage regulator is very inefficient (current in = current out, so if you need 100mA at 5V, the linear voltage regulator requires 100mA at 24V, so you loose 1.9W in this module). Therefore, it is recommended to disconnect the linear voltage regulator from the board, and use the 5V from the switched mode power supply.

L9958 GND---GND L9958 VCC---Arduino 5V L9958 EN---Arduino 5V L9958 DI---GND L9958 DIR---Arduino MOTOR_DIR L9958 PWM---Arduino MOTOR_PWM L9958 MOTOR(+)---motor(+) L9958 MOTOR(-)---motor(-) L9958 POWER(+)---battery(+) L9958 POWER(-)---battery(-)

L298N

Особенности: up to 4A Notice: When using a L298N-motor driver, both H-bridges (2A) should be connected in parallel, so that both bridges drive a single motor (max. 4A):

Connect in parallel:

IN1 with IN4 IN2 with IN3 OUT1 with OUT4 OUT2 with OUT3

(Do NOT disconnect the SENSE-lines, except when you want to measure current by a 'shunt' resistor).

Make sure there is a jumper on both ENA and ENB. Also, make sure there is a jumper on S1.

Mower motor and driver

The Ardumower mower motor features:

- Fast enough to cut the lawn (3150 rpm)

- Enough torque (140 mNm / 46 W)

- Quiet mowing (you cannot hear it)

- 24V, load current ~1.0A (L=2.8mH, R=1.9ohm)

For a the mowing motor, a MOSFET circuit is used. The MOSFET transistor IRLIZ44N (alternatives: IRF1404, IRL540N, RFP30N06LE, FQP30N06L) can already switch a current of 30A at the Arduino 5V control signal (N-LogL). The 10K resistor pulls down to ground when the Arduino starts. The 180 Ohm resistor limits the current at the Gate caused by level switches to about 30mA. The diode (MBR1045) protects the circuit against current caused by motor induction. A current sensor module (ACS712-30A) is connected in series with the motor.

![]() Security note: For security reasons, always remove mower blades in your first tests!

Security note: For security reasons, always remove mower blades in your first tests!

NOTE: only for demonstration! See real schematics for concrete wiring

Choosing a driver

When purchasing a motor driver, consider...

- max. thermal load (short-circuit current)

- price

Starting current

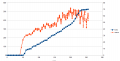

Here are some measurements of the Ardumower motor's starting current (peak):

Starting current:

- Gear motor: 15A (starting current peak)

- Mowing motor: 20A (starting current peak)

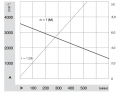

Short-circuit current

To not damage the motor driver on the first run, find out the maximum current that can flow through your motors. In other words, find out the 'short-circuit' current. Typical measurement installation:

Battery === Ampere meter === Motor

The Amperemeter (e.g. model making) should be able to measure the maximum current (e.g. 30A). The motor to be measured is mechanically blocked (so it cannot rotate).

Warning

- always remove blades

- only connect battery for a short period (1-5 seconds)

- always use cables with sufficient wire cross section

Example measurement:

- Rotenbach SPM08-320

- Wheel motor: 8A

- Mowing motor:

- Ambrogio L50

- Wheel motor: 4,5A

- Mowing motor: 22A

- Tianchen TC-G158

- Wheel motor: 5,4A

- Mowing motor: 16A (both 32A)

The measured current will only flow in 'worst-case' scenarios, which means when the motor starts or when it is blocked and it will only flow for a short time (as your battery might not deliver the high current constantly, and so current and voltage will break down).

Current sensor

To detect certain conditions (robot drives against obstacle, motor blocks etc.), the motor current should be monitored constantly. There are two approaches for sensing current.

Approach "Hall sensor module"

This is the recommended approach for sensing current. These current sensor modules are available for different current ranges.

- ACS712ELC-05A (185mV/A, max. 5A)

- ACS712ELC-20A (100mV/A, max. 20A)

- ACS712ELC-30A (66mV/A, max. 30A)

- The lower the range, the more precise the measurement.

Approach "Shunt resistor (circuit)"

The current flows across a very small resistor (0.5 Ohm) and the voltage drop is measured