Ardumower PCB: Unterschied zwischen den Versionen

(→Schematics) |

(→Schematics) |

||

| Zeile 52: | Zeile 52: | ||

<gallery> | <gallery> | ||

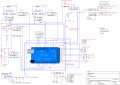

File: Ardumower_schematics.png | v0.9.3 code | File: Ardumower_schematics.png | v0.9.3 code | ||

| + | File: | SVN code | ||

</gallery> | </gallery> | ||

Version vom 14. September 2014, 10:04 Uhr

Inhaltsverzeichnis

Abstract

This page describes how to assemble the Ardumower PCB, flash the Arduino and configure the robot mower.

The controller is built around a ready microcontroller board (Arduino Mega 2560 using 54 I/O pins).

Needed parts

All parts can be purchased as complete kits via the shop ![]() .

.

v0.9.3

If you know nothing about code, choose v0.9.3 and these parts:

- Main functions

- Arduino cable (female-female and male-female jumper cable)

- 1 x Arduino Mega 2560

- 1 x DC voltage step-down module (LM2596)

- 2 x L298N motor driver module

- 3 x current sensor module ACS712-5

- 1 x current sensor module ACS712-30

- 1 x mower motor driver circuit: MOSFET IRLIZ44N, Diode MBR1045, Schottky-Diode 10A, Resistors (10K, 180 Ohm)

- Resistors (2 x 47K, 2 x 5K), Capacitors ( Fuse F20A250V

- Piezo buzzer (0,1W), button, ON/OFF switch 10A

- Perimeter sender (optional)

- 1 x Arduino Nano

- Coil 220µH, Elko 2,2µF/160V, Resistors (1 Ohm, 1K, 4,7K), Diode 1N4448

- 1 x DC voltage step-down module (LM2596)

- 1 x L298N motor driver module

- Perimeter receiver (optional)

- 1 x Arduino Nano

- 2 x Arduino Sound Sensor Module (must use LM386)

- Capacitors (2 x 4,7nF, 2 x 100nF), Resistors (2 x 200k), 2 x Receiver coils 85mH

- Additional modules

- 1 x HC-SR04 ultrasonic sensor module (optional)

- 1 x GY80 module (gyro, accel. compass) (optional)

- 1 x DS1307 realtime clock module (optional)

- 1 x Bluetooth module (for phone control)

SVN version

If you want to be ready for the future, choose SVN and the parts listed there.

Schematics

PCB assembly

...

...add a high resolution picture of the assembled PCB here...

Power supply

It is recommended to use a voltage step-down converter (e.g. module using LM2596) to generate the 5V voltage for the Arduino and all additional modules. Before connecting, set the voltage of the converter to 5V.

![]() Warning : never connect more than 5V on the Arduino 5V pins, or you will damage the Arduino. Therefore, always measure the 5V voltage before connecting it to the Arduino 5V pin!

All components together (as shown in the schematics) need about 5W power.

Warning : never connect more than 5V on the Arduino 5V pins, or you will damage the Arduino. Therefore, always measure the 5V voltage before connecting it to the Arduino 5V pin!

All components together (as shown in the schematics) need about 5W power.

Flashing the Arduino

Arduino Version

It is verry Importent that you use the Arduino Version 1.5.6-r2 or above AND select the right Board.

...

First-time calibration

Wheel motors

![]() Security note: For security reasons, always remove mower blades in your first tests!

Security note: For security reasons, always remove mower blades in your first tests!

Initially, you should verify that the wheel motors are controlled correctly and in the right direction. The software offers a diagnostic mode. Open the serial console in the Arduino IDE (CTRL+SHIFT+M) and set the baudrate to 19200. The motor and sensor values should appear constantly:

20 OFF spd 0 0 0 sen 0 0 0 bum 0 0 son... 21 OFF spd 0 0 0 sen 0 0 0 bum 0 0 son... 22 OFF spd 0 0 0 sen 0 0 0 bum 0 0 son... 23 OFF spd 0 0 0 sen 0 0 0 bum 0 0 son... 24 OFF spd 0 0 0 sen 0 0 0 bum 0 0 son... ...

Now, press the key ‘t’ on the keyboard, and confirm using ENTER. The diagnostic mode should appear, and you can test your motors.

ADC calibration

If using perimeter v2: Run the ADC calibration once ("pfodApp->ADC Calibration"), so that the received signal is symmetric around zero.

Diagnostic

Each time a sensor triggers, its corresponding sensor counter increases. The sensor trigger counters as well as the current sensor values can be viewed on the serial console. The following values are shown for the trigger counters in the serial console:

- Time of state machine's state (ms)

- loop()-counts per second

- choosen Verbose-Mode (0=counter readings/1=current values/2=current values)

- current state machine state (FORW, REV, ROLL etc.)

- drive home? (1/0)

- "spd" - Control/speed motors: left (PWM), right (PWM), mower (RPM)

- "sen" - Current limit exceeded counter motors: left, right, mower

- "bum" - bumper counter: left, right

- "son" - Ultrasonic-distance threshold exceeded (counter)

- "pit/roll" - Tilt (computed by acceleration sensor)

- "com" - compass course

- "per" - Perimeter loop detected: counter

- "bat" - Battery voltage

- "chg" - Charging current

Using the key 'v', you can toggle between summary of sensor (counters) and current sensor values.

Additionally, you can use pfodApp (Android) to plot the sensors (trigger counters and current values) over time:

Starting the mower

To start the mower, you need to add a button and a buzzer:

pinButton —o Button o— GND (button for ON/OFF)

pinBuzzer —o Buzzer o— GND (Piezo buzzer)

Now, press the button as long as you hear the beeps:

Mode (press button for x beeps):

1 beeps : Normal mowing (using blade modulation if available) 2 beeps : Normal mowing (without blade modulation) 3 beeps : Drive by model remote control (RC) 4 beeps : Drive without mowing 5 beeps : Find perimeter and track it

Error counter / error beeps

If there's a communication problem or another serious problem, the error counter increases. The error counter can be monitored via pfodApp. Additionally, the robot mower will beep when started.

I2C bus / error beeps

Several components (Arduino Nano, RTC, IMU, etc.) are communicating via the I2C bus (SDA/SCL wires). These wires should be very short (maybe even twisted) and they should be far away from DC converter and motor drivers. If there's a communication problem, the error counter will increase and robot will beep when started. The error counter can be monitored via pfodApp.

Config files

You can adapt the Ardumower code to your own robot mower hardware using the config file:

- config.h (v9.0.3)

- mower.cpp (SVN version)

Config files translate the commands of the main program into the specific hardware (i.e. actuators and sensors) - that allows us to adapt the main program to different robot mowers:

Example:

The main program wants to drive the left wheel motor with speed 100. The chosen robot config file is called by the main program with this command:

setActuator(ACT_MOTOR_LEFT, 100)

The actual config file will execute this command by calling the specific motor driver:

setL298N(pinMotorLeft, pinMotorLeftPWM, 100)

To enable a sensor, remove the comment of that line. To disable a sensor, comment the line with a double slash (//).

pfodApp

The configuration of the robot mower can be set via pfodApp.

Important: If you flashed a new version, reset all settings via pfodApp once (Settings->Factory reset). This will delete all existing settings. Old settings can produce malfunction if the internal settings format has changed.