Raindancer Firmware (English): Unterschied zwischen den Versionen

Roland (Diskussion | Beiträge) (→config.h) |

Roland (Diskussion | Beiträge) (→Overview) |

||

| (95 dazwischenliegende Versionen von 2 Benutzern werden nicht angezeigt) | |||

| Zeile 1: | Zeile 1: | ||

| − | + | Folks, English is not my native language. If you don't understand something or find a mistake, please inform me on the forum (name: Roland) or correct the mistake by yourself. Thank you very much. | |

| + | |||

| + | '''This documentation is for firmware version 2.x.x.''' | ||

| + | |||

| + | |||

| + | '''The documentation of version 1.1.1 you can find here [[Raindancer Firmware V1.x.x (English) | Raindancer Firmware V1.1.1]]''' | ||

| − | |||

=Download= | =Download= | ||

[https://github.com/Ardumower/Raindancer Github Download] | [https://github.com/Ardumower/Raindancer Github Download] | ||

| − | ( | + | (On Github download the Zip-File with the green button) |

The Raindancer firmware is located in the directory code\Raindancer | The Raindancer firmware is located in the directory code\Raindancer | ||

| Zeile 17: | Zeile 21: | ||

The Raindancer firmware is based on the code of the Nucleomower which was realized with the development board STM32 Nuleo 411RE in 2016/2017. The firmware was then converted to Ardumower PCB 1.3 in 2017/2018. It pursues the goal of getting a stable system with as little hardware as possible, which works all year round and provides a good mowing result with the chaos principle. | The Raindancer firmware is based on the code of the Nucleomower which was realized with the development board STM32 Nuleo 411RE in 2016/2017. The firmware was then converted to Ardumower PCB 1.3 in 2017/2018. It pursues the goal of getting a stable system with as little hardware as possible, which works all year round and provides a good mowing result with the chaos principle. | ||

| − | The firmware has following '' 'Workflow' '': | + | The firmware has the following '' 'Workflow' '': |

The Mower is in the charging station. The Mower drives from the charging station a predetermined distance along the perimeter to an area and then begins to mow after the chaos principle. The mowing time is approx. 130min-150min with the original Ardumowerkomponents. After the battery voltage has dropped to 23.7V, the robot looks for the perimeter cable and drives it to the charging station. Once in the charging station, the battery is charged. The next mowing operation is restarted via the mobile phone with a range command. (The robot can also be operated without a charging station.) | The Mower is in the charging station. The Mower drives from the charging station a predetermined distance along the perimeter to an area and then begins to mow after the chaos principle. The mowing time is approx. 130min-150min with the original Ardumowerkomponents. After the battery voltage has dropped to 23.7V, the robot looks for the perimeter cable and drives it to the charging station. Once in the charging station, the battery is charged. The next mowing operation is restarted via the mobile phone with a range command. (The robot can also be operated without a charging station.) | ||

| − | The firmware was developed for robots with the drive motor rear, but can also be used for the original Ardumower chassis. | + | The firmware was developed for robots with the drive motor rear, but can also be used for the original Ardumower chassis. |

| + | If the mower reaches the perimeter wire it will continue driving for approx. 20cm. Then the rmower drives back and will be further rotated at a random angle. | ||

Internally in the firmware, distances are traveled in cm. This means that encoders are needed. | Internally in the firmware, distances are traveled in cm. This means that encoders are needed. | ||

| − | For the '' ' | + | For the '' 'Perimeterrecognition' '' a 128-bit signal is used. Therefore, the Raindancer transmitter (sender) software must be installed on the transmitter. 2 perimeter receivers are needed. As you approach the perimeter cable, the robot slows down. |

| − | If the robot does not recognize the signal for 2 seconds, it stops and switches off the motors. If it recognizes the signal again, it continues. | + | If the robot does not recognize the signal for 2 seconds, it stops and switches off the motors. If it recognizes the signal again, it continues. If the perimeter signal is too weak in the middle of the lawn, a GPS area can be configured. If the robot is in this area, it is assumed to be within the perimeter loop. |

| − | + | The firmware supports a head charging station and a through charging station. Using the charging station can be switched off in the software. Then the robot stops at the perimeter when the battery voltage drops below 23.7V. For charging, the robot can then be switched off, connected to the charging cable and switched on again. The robot then goes into charging mode. If the voltage drops below 21.7V, the undervoltage trip will trip if it is not bypassed. | |

With the original motors and wheels, the robot drives at a speed of approx. 1200m / h. | With the original motors and wheels, the robot drives at a speed of approx. 1200m / h. | ||

| Zeile 37: | Zeile 42: | ||

The firmware was optimized for '' 'not with the perimeter wire fenced obstacles' '' on the lawn. Instead of driving at full speed against the obstacle, the speed is reduced from a certain distance and drove gently against the obstacle. Prerequisite for this are sonar sensors. This feature is optional. | The firmware was optimized for '' 'not with the perimeter wire fenced obstacles' '' on the lawn. Instead of driving at full speed against the obstacle, the speed is reduced from a certain distance and drove gently against the obstacle. Prerequisite for this are sonar sensors. This feature is optional. | ||

The robot supports a self-made Bumperduino with two MaxSonar sonar sensors and an MPX5010DP FREESCALE pressure sensor for a pressure wave hose. | The robot supports a self-made Bumperduino with two MaxSonar sonar sensors and an MPX5010DP FREESCALE pressure sensor for a pressure wave hose. | ||

| − | https://github.com/ | + | https://github.com/Ardumower/Raindancer/tree/master/DipTrace/DistanceBumperSensorDistanceBumperSensor.pdf |

| − | The evaluation is done by an Arduino Nano, which is connected to the PinUserSwitch2 / 3 of the PCB1.3. Upon detection of an obstacle with the sonar sensors, the robot slows down and bumped gently against the obstacle where the bumper or bumper | + | The evaluation is done by an Arduino Nano, which is connected to the PinUserSwitch2 / 3 of the PCB1.3. Upon detection of an obstacle with the sonar sensors, the robot slows down and bumped gently against the obstacle where the bumper or bumper duino triggers. |

The board is relatively simple. This allows them to be easily soldered together on a laboratory board. The MaxSonar sensors can be omitted and a separate solution can be connected to the Nano. | The board is relatively simple. This allows them to be easily soldered together on a laboratory board. The MaxSonar sensors can be omitted and a separate solution can be connected to the Nano. | ||

The sensor for the pressure wave hose can be omitted and only the sonar sensor is used. Another option for an approach solution is to expand the current Raindancer software. | The sensor for the pressure wave hose can be omitted and only the sonar sensor is used. Another option for an approach solution is to expand the current Raindancer software. | ||

The original Ardumower ultrasonic sensors are currently not supported. | The original Ardumower ultrasonic sensors are currently not supported. | ||

| − | The serial interface is used for the operation. On the mobile phone is the software Arduino | + | The serial interface is used for the operation. On the mobile phone is the software Arduino Centrale is used (free with advertising or without advertising for a few euros). In Arduino Centrale, buttons can be configured with commands. The operation is via command line commands. The send line must be terminated with CR. The output is automatic shown on the console or on the mobile phone, depending on where the command was just entered. |

Most commands are grouped by services. The group corresponds to the services mentioned in the software. The command following the service is then separated by a dot. Spaces are skipped and have no meaning. | Most commands are grouped by services. The group corresponds to the services mentioned in the software. The command following the service is then separated by a dot. Spaces are skipped and have no meaning. | ||

This is useful when using the mobile phone, where a space is inserted after a period. | This is useful when using the mobile phone, where a space is inserted after a period. | ||

| Zeile 51: | Zeile 56: | ||

Parameters are separated by a comma. | Parameters are separated by a comma. | ||

| − | Example: pc.cm,60,30 | + | Example: pc.cm,60,60,30,30 //drives left wheel 60cm at 30% speed and right 60cm at 30% speed (//drives... does not belong to the command) |

This addresses the Positioncontrol service. Drive 60cm at the speed of 30% | This addresses the Positioncontrol service. Drive 60cm at the speed of 30% | ||

| Zeile 60: | Zeile 65: | ||

The software is modular. The individual modules are hardly influence each otherl. This makes it relatively easy to modify or extend something. | The software is modular. The individual modules are hardly influence each otherl. This makes it relatively easy to modify or extend something. | ||

| − | https://github.com/ | + | https://github.com/Ardumower/Raindancer/tree/master/Documentation/SoftwareStructure.pdf |

The UMLET software was used to display and edit the Structure software. | The UMLET software was used to display and edit the Structure software. | ||

| Zeile 72: | Zeile 77: | ||

https://www.electronic-software-shop.com/support/kostenlose-datei-viewer/?xoid=oep38ca4ehqn37a7dn3rnrpie6 | https://www.electronic-software-shop.com/support/kostenlose-datei-viewer/?xoid=oep38ca4ehqn37a7dn3rnrpie6 | ||

The files of the BHT are here: | The files of the BHT are here: | ||

| − | https://github.com/ | + | https://github.com/Ardumower/Raindancer/tree/master/Documentation |

The robot knows two modes: Manual and Auto. In manual mode, all services are running, but the Behavior Tree (BHT) is off. In auto mode, the BHT is activated. | The robot knows two modes: Manual and Auto. In manual mode, all services are running, but the Behavior Tree (BHT) is off. In auto mode, the BHT is activated. | ||

| Zeile 81: | Zeile 86: | ||

If the robot is in MANUAL mode, it can be switched to automode using command A. If the robot then recognizes the perimeter signal, it starts mowing. | If the robot is in MANUAL mode, it can be switched to automode using command A. If the robot then recognizes the perimeter signal, it starts mowing. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

=For minimum commissioning, the following requirements should be met= | =For minimum commissioning, the following requirements should be met= | ||

| Zeile 129: | Zeile 114: | ||

Select the chassis form. Only one parameter may be set to true. | Select the chassis form. Only one parameter may be set to true. | ||

| − | #define ARDUMOWER_CHASSIS | + | #define ARDUMOWER_CHASSIS true |

#define PARANELLO_CHASSIS false | #define PARANELLO_CHASSIS false | ||

| − | #define RAINDANCER_CHASSIS | + | #define RAINDANCER_CHASSIS false |

In config.h go then to the code section, which belongs to your choice and change this section. | In config.h go then to the code section, which belongs to your choice and change this section. | ||

| Zeile 162: | Zeile 147: | ||

#define CONF_DISABLE_PERIMETER_SERVICE false // Disables perimeter sensor | #define CONF_DISABLE_PERIMETER_SERVICE false // Disables perimeter sensor | ||

#define CONF_DISABLE_RTC_SERVICE true // Disables rtc sensor | #define CONF_DISABLE_RTC_SERVICE true // Disables rtc sensor | ||

| − | #define CONF_DISABLE_EEPROM_SERVICE true | + | #define CONF_DISABLE_EEPROM_SERVICE true // Disables EEPROM requests |

| − | #define CONF_DISABLE_BATTERY_SERVICE true | + | #define CONF_DISABLE_BATTERY_SERVICE true // Disables battery sensor |

| − | #define CONF_DISABLE_CHARGE_SERVICE true | + | #define CONF_DISABLE_CHARGE_SERVICE true // Disables charge system service |

| + | #define CONF_DISABLE_RAIN_SERVICE true // Disables rain sensor | ||

| + | #define CONF_DISABLE_DHT_SERVICE true // Disables temp sensor | ||

| + | #define CONF_DISABLE_GPS true // Disables GPS service | ||

| − | #define CONF_DISABLE_MOTOR_STALL_CHECK | + | #define CONF_DISABLE_MOTOR_STALL_CHECK true // Disables the motor stall/encoder check in closed loop control |

| − | #define CONF_DISABLE_MOW_MOTOR | + | #define CONF_DISABLE_MOW_MOTOR false // Disables the mow motor |

#define CONF_DISABLE_CHARGINGSTATION true | #define CONF_DISABLE_CHARGINGSTATION true | ||

| Zeile 185: | Zeile 173: | ||

Enter H here. Thereafter, all available commands are displayed. It is a good ideas to copy and save the commands to a file, so that you can look at it when you need. | Enter H here. Thereafter, all available commands are displayed. It is a good ideas to copy and save the commands to a file, so that you can look at it when you need. | ||

| + | |||

| + | If after compilation following warning occure, they can be ignored: | ||

| + | pinman.cpp: 18:0: warning: "PWM_FREQUENCY" redefined [enabled by default] | ||

| + | #define PWM_FREQUENCY 3900 | ||

| + | pinman.cpp: 19:0: warning: "TC_FREQUENCY" redefined [enabled by default] | ||

| + | #define TC_FREQUENCY 3900 | ||

= QUICK START TO MOW = | = QUICK START TO MOW = | ||

| − | + | The aim of this chapter is to become more familiar with the operation, and to configure the robot to the extent that the perimeter sensors | |

| − | + | work and you can mow within the perimeter. | |

| − | + | The robot is connected via the console cable. Speed: 115200 | |

==Errorhandling== | ==Errorhandling== | ||

| − | + | If the firmware detects an error, this goes into the Errormode. The Mower stops and the mow motor is switched off. The services continue to run. The first error occurred is latched. | |

| − | + | The error is then sent to the console or bluetooth (BT) every 2 seconds, depending on what was last active or activated by sending a character. If you has started the mower via Bluetooth, the error is then shown on BT. | |

| − | + | To disable the error, the following commands must be entered one after the other: | |

reset //reset error and motor faults | reset //reset error and motor faults | ||

M //activate manual mode | M //activate manual mode | ||

| − | + | The error command can be used to display the error log. The error log shows the history of the traversed running nodes of the BHT as well as various other events. It is 5000 characters tall. | |

error //show errormessage | error //show errormessage | ||

| − | + | The show.hist command displays the last direction of rotation and other parameters. | |

show.hist //show history | show.hist //show history | ||

| − | + | The last entered values will be displayed first, so that they are above! | |

| + | |||

| − | + | After disabling the error, the Mower can be started again with: | |

A | A | ||

| − | + | However, both coils must be in the perimeter for that. | |

| − | == | + | ==To get warm: Configuration of the battery service== |

| − | + | The battery service determines the voltage of the battery and makes it available to the BHT. | |

| − | + | Activate the battery service in config.h and then re-install the software. | |

#define CONF_DISABLE_BATTERY_SERVICE false | #define CONF_DISABLE_BATTERY_SERVICE false | ||

| − | + | Enter the command: | |

| − | + | bat.show | |

| − | + | It should display the correct battery voltage. | |

| − | + | If this deviates by more than 0.2V, then this can be adjusted with the constants | |

| − | + | #define BATTERYFACTOR_BS 11.0f // Equivalent to (100 + 10) / 10 Voltagedivider | |

| − | + | #define DIODEDROPVOLTAGE_BS 0.4f | |

| − | + | These constants are defined in batterySensor.h. | |

| − | + | ||

| − | + | The voltage in batterySensor.h is calculated as follows | |

sensorValue = aiBATVOLT.getVoltage(); | sensorValue = aiBATVOLT.getVoltage(); | ||

float readVolt = sensorValue * BATTERYFACTOR_BS + DIODEDROPVOLTAGE_BS; // The diode sucks 0.4V | float readVolt = sensorValue * BATTERYFACTOR_BS + DIODEDROPVOLTAGE_BS; // The diode sucks 0.4V | ||

| − | == | + | == Commissioning of the motors == |

| − | + | The first thing to check is whether the motors are turning and whether they are turning in the right direction. | |

| − | + | For this purpose, the motors are controlled directly with a PWM specification. This means, there is no control of the speed based on the encoder. The speed control loop is open (open loop); | |

| − | + | The command clc.mt, 1,150 causes the clc service to send the input PWM of 150 directly to the motor. Maximum for the PWM is 255. | |

| − | + | A 1 controls the left engine, a 2 the right. | |

| − | + | Enter the command: | |

clc.mt,1,150 | clc.mt,1,150 | ||

| − | |||

| − | + | This activates the motor (1) on the left directly with a PWM of 150. | |

| − | + | The wheel is then Stopped with: | |

clc.mt,0,0 | clc.mt,0,0 | ||

| − | + | The wheel on the left should turn forward. If it turns backwards, the cable at the plug must be reversed. | |

| − | + | Should the wheel not turn, it can still be tried with a higher PWM of e.g. 200. | |

| − | + | The wheel should definitely turn even at a PWM of 50 (better less). | |

| − | + | The same for the right wheel (2): | |

clc.mt,2,150 | clc.mt,2,150 | ||

| − | + | The wheel is then Stopped with: | |

clc.mt,0,0 | clc.mt,0,0 | ||

| Zeile 267: | Zeile 260: | ||

Achtung: Wenn die PWM zu hoch gesetzt wird, z.B. 18000Hz, dann drehen sich die Räder bei niedriger PWM von z.B. 60 nicht mehr. Es kommt dann ein Fehler, dass bei Vorgegebener PWM von 60 die Geschwindigkeit 0 ist. | Achtung: Wenn die PWM zu hoch gesetzt wird, z.B. 18000Hz, dann drehen sich die Räder bei niedriger PWM von z.B. 60 nicht mehr. Es kommt dann ein Fehler, dass bei Vorgegebener PWM von 60 die Geschwindigkeit 0 ist. | ||

| − | == | + | == Commissioning the encoder == |

| − | + | It it checked if the encoders work and if they count in the right direction. | |

| − | + | The encoder routine has two counters per wheel. Once an absolute counter (absEnc), which always counts positive no matter in which direction the wheel turns. | |

| − | + | And a positive / negative counter (enc), which counts up when driving forward and counts down when reversing. | |

| − | + | Enter the command | |

| − | clc.mt,1,150 | + | clc.mt, 1,150 |

| − | + | to make the left wheel turn. | |

| − | + | Enter then | |

| − | clc.enc | + | clc.enc |

| − | + | This will display the encoder values from the left and right wheels. | |

| − | + | The output is terminated with the command: h. | |

| − | + | Both displayed counters of the left wheel (1) must now count up. | |

| − | + | Example: | |

| − | + | Engine 1 = left - should not count if only the right engine is running. | |

| − | + | Engine 2 = right - should not count if only the left engine is running. | |

| − | !03,motor 1 enc: 972 absEnc: 972 rpm: 2.596326 | + | ! 03, motor 1 enc: 972 absEnc: 972 rpm: 2.596326 m / h: 125.773315 deltaTicks: 2 deltaTime: 32986us |

| − | !03,motor 2 enc: 974 absEnc: 974 rpm: 3.325853 | + | ! 03, motor 2 enc: 974 absEnc: 974 rpm: 3.325853 m / h: 161.113647 deltaTicks: 2 deltaTime: 33445us |

| − | !03,motor 1 enc: 974 absEnc: 974 rpm: 2.923552 | + | ! 03, motor 1 enc: 974 absEnc: 974 rpm: 2.923552 m / h: 141.625061 deltaTicks: 2 deltaTime: 33156us |

| − | !03,motor 2 enc: 975 absEnc: 975 rpm: 2.678638 | + | ! 03, motor 2 enc: 975 absEnc: 975 rpm: 2.678638 m / h: 129.760696 deltaTicks: 1 deltaTime: 33144us |

| − | !03,motor 1 enc: 976 absEnc: 976 rpm: 3.132316 | + | ! 03, motor 1 enc: 976 absEnc: 976 rpm: 3.132316 m / h: 151.738159 deltaTicks: 2 deltaTime: 32857us |

| − | !03,motor 2 enc: 976 absEnc: 976 rpm: 2.296233 | + | ! 03, motor 2 enc: 976 absEnc: 976 rpm: 2.296233 m / h: 111.235962 deltaTicks: 1 deltaTime: 32859us |

| − | !03,motor 1 enc: 978 absEnc: 978 rpm: 3.251686 | + | ! 03, motor 1 enc: 978 absEnc: 978 rpm: 3.251686 m / h: 157.520752 deltaTicks: 2 deltaTime: 32998us |

| − | + | The example shows that the encoders are counting up. '' 'Example motor 1' '': enc: 972 then enc: 974, then enc: 976 ... '' 'Example motor 2' '': enc: 972 then enc: 975, then enc: 976 ... | |

| − | + | If the enc value counts negative when driving forward you can configure it in the config.h: | |

| − | #define CONF_LEFT_ENCODER_INVERSE | + | #define CONF_LEFT_ENCODER_INVERSE false |

| − | #define CONF_RIGHT_ENCODER_INVERSE | + | #define CONF_RIGHT_ENCODER_INVERSE false |

| − | + | To do this, set CONF_LEFT_ENCODER_INVERSE to true for the left wheel. Set CONF_RIGHT_ENCODER_INVERSE to true for the right wheel. | |

| − | + | Do the same for the right wheel: | |

| − | clc.mt,2,150 | + | clc.mt, 2,150 |

| − | + | Command is stopped with clc.mt, 0,0. | |

| − | + | After the lines in the config.h have been set correctly, recompile, play and retest! | |

| − | ==Check | + | == Check of the closed loop control service == |

| − | + | The closed loop control (clc) service controls the speed of a wheel and thus also the straightforward movement of the robot. There is one service for each wheel so there are two services in total. The service internally calculates the speed of the wheel with the aid of the encoder values and then sets the necessary PWM to reach the specified speed (closed loop). The speed is given in%. 100% refering to the constant CONF_MAX_WHEEL_RPM in the config.h. | |

| − | + | With the command clc.v,30 both services are commanded to turn the wheel at a speed (v) of 30%. Thus, both wheels should turn forward. | |

| − | + | Enter: | |

| − | clc.v,30 | + | clc.v, 30 Moving forward with speed 30% |

| − | + | then | |

| − | clc.v,s | + | clc.v, s stop engine |

| − | + | then | |

| − | clc.v,-30 | + | clc.v, -30 drives reverse with speed 30% |

| − | + | If everything is working, then continue. Otherwise check encoders and drivedirection again. | |

| − | mot.cur | + | mot.cur Shows the motor current. |

| − | ==Check | + | == Check the position control services == |

| − | + | The Position Control Service (pc) is used to drive the wheel a certain way or to turn the wheel a certain angle. There is one service per wheel. | |

| − | + | With the command pc.a,360,80 both wheels are comanded to: Turn the wheels an angle of 360 degrees with a maximum speed of 80%. | |

| − | + | Make a mark on a wheel to see how far it turns. | |

| − | + | ||

| − | pc.a,360,80 | + | pc.a, 360,80 Rotates both wheels forward by 360 degrees with 80% speed if everything is configured correctly. |

| − | pc.a,-360,80 | + | pc.a, -360,80 Rotates both wheels backwards by 360 degrees with 80% speed if everything is configured correctly. |

| − | + | The Position Control can be stoped with the command | |

pc.s | pc.s | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | If the wheel does not turn 360 degrees, the value CONF_ENCTICKSPERREVOLUTION in config.h appears to be wrong. For the original engines from the Ardumower shop, the value of 1060 is given. | |

| − | + | In addition, the constant CONF_RADUMFANG_CM is important for the calculation to be correct to drive a particular path in cm. | |

| − | + | Since the engine monitoring was switched off in the beginning in the config.h, it is now time to switch on again. | |

| + | Motor monitoring checks whether the encoders deliver values when the motors are turning, whether they are turning in the right direction, or whether the motor is actually turning when a PWM is applied. | ||

| − | #define CONF_DISABLE_MOTOR_STALL_CHECK | + | To enable motor monitoring in config.h, set the value CONF_DISABLE_MOTOR_STALL_CHECK to false. |

| + | #define CONF_DISABLE_MOTOR_STALL_CHECK false | ||

| − | + | Recompile and upload. Then try again. | |

| − | + | No errors should be displayed. | |

| − | + | If everything works, the robot can be put on the wheels. | |

| − | + | Further tests can still be performed (note that the USB cable should be long enough, preferably use an extension); | |

| − | + | Drive a certain way in cm | |

| − | pc.cm,60,30 | + | pc.cm,60,60,30,30 drives 60cm forward with the speed of 30% |

| − | pc.cm,-60,30 | + | pc.cm,-60,-60,30,30 drives 60cm backwards with the speed of 30% |

| − | + | Turning a certain angle. Prerequisite: CONF_ENCTICKSPERREVOLUTION, CONF_RADUMFANG_CM and CONF_DISTANCE_BETWEEN_WHEELS_CM are configured correctly. | |

| − | turnto,360,30 | + | turnto, 360,30 Turn the robot 360 degrees CW (clockwise) |

| − | turnto,-360 | + | turnto, -360.30 Turn the robot 360 degrees CC (counter clockwise) |

| − | + | If the robot does not turn 360 degrees, the constant CONF_DISTANCE_BETWEEN_WHEELS_CM in config.h is probably wrong. | |

| − | == | + | ==Mowmotor commissioning== |

| − | + | The mowing motor does not use an encoder. It is operated with a PWM of 255. The PWM of 255 is not immediately given to the engine. It ramps up the PWM from 0 to 255. | |

| − | + | The same applies to the braking of the engine. It may happen that a motor fault is displayed when the engine is decelerating. This is because the inertia of the mowmotor disc tends to continue to rotate the motor, thus retroactively injecting a current into the motor driver that exceeds the limits such that the tri-state outputs of the driver go to high-impedance. If this happens, the error can be reset with the reset command. | |

Befehl eingeben: | Befehl eingeben: | ||

| Zeile 383: | Zeile 374: | ||

t //mow motor stop | t //mow motor stop | ||

| − | + | It may be that when stopping the motor a fault comes up. Reset this with the command reset. | |

| − | mot.curm // | + | mot.curm //indicates the mowing motor current. |

| − | + | If the PCB1.3 is used, the mower motor current is probably displayed incorrectly here. See: Adjusting the mower motor current in Tune Up | |

| − | + | This can be done later and is not so important for the first mowing operation. | |

| − | ==Perimeter | + | ==Perimeter Commissioning== |

| − | + | The Raindancer firmware works with two coils. This determines the angle at which the robot meets the perimeter. Accordingly, it is decided whether CC or CW is rotated. The perimeter signal must be received all the time while mowing. If the signal is not received for 2 seconds, the robot will stop and continue as soon as the signal is received again. The time that a non-receive is tolerated is set with the parameter CONF_PER_SIGNAL_LOST_TIME in the config.h. With this it is possib to bridge "Receiving holes" in the middle of the lawn. Disadvantage is, if the transmitter fails exactly when the robot is at the perimeter, it may be that the robot travels this set time outside the perimeter loop. | |

| − | + | Prerequisite for commissioning: | |

| − | + | The spools of the robot must be within the perimeter loop for commissioning. | |

| − | + | The Raindancer transmitter firmware must be installed on the transmitter. | |

| − | + | First check is if the signal is detected. | |

| − | + | You can see the calculated value of the individual coils as follows: | |

| − | per.resultl | + | per.resultl for left coil |

| − | + | and | |

| − | + | per.resultr for right coil. | |

| + | The example below shows that the BAD has not received a valid signal. | ||

| + | It is important here that no BAD is displayed. The received amplitude is behind mag :. The signal quality can be seen on the Peak Signal Noise Ratio psnr. | ||

Beispiel per.resultl | Beispiel per.resultl | ||

| Zeile 419: | Zeile 412: | ||

mag: 5 peak @ 11 : 5 peak2 @ 153 : 5 MSE: 3.286 psnr: 7.607 psnr2: 7.607 ratio: 1.000 BAD | mag: 5 peak @ 11 : 5 peak2 @ 153 : 5 MSE: 3.286 psnr: 7.607 psnr2: 7.607 ratio: 1.000 BAD | ||

| − | + | End the output with h. | |

| − | + | Both coils should detect the signal, so do not indicate a BAD. Also not sporadicly! | |

| − | + | Next, the polarity of the signal must be configured. Enter: | |

| − | per.show | + | per.show. (switch off output with h) |

| − | + | If the coil is inside the perimeter, the amplitude of the coil must be positive. | |

| − | + | The detected perimeter amplitudes are now shown. | |

| − | ML | + | ML indicates the amplitude of the left coil, MR the amplitude of the right coil. |

!03, ML: -305 MR: 331 magMax:332 magMedL%: 0 magMedR%: 102 | !03, ML: -305 MR: 331 magMax:332 magMedL%: 0 magMedR%: 102 | ||

| Zeile 440: | Zeile 433: | ||

!03, ML: -326 MR: 324 magMax:332 magMedL%: 0 magMedR%: 102 | !03, ML: -326 MR: 324 magMax:332 magMedL%: 0 magMedR%: 102 | ||

| − | + | However, one can see here that the magnetude on the left coil is negative. | |

| − | + | Inside the perimeter loop, this must be positive. | |

| − | + | This can be set in the config.h: | |

#define CONF_LEFT_COIL_INVERSE true | #define CONF_LEFT_COIL_INVERSE true | ||

| − | #define CONF_RIGHT_COIL_INVERSE | + | #define CONF_RIGHT_COIL_INVERSE false |

| − | + | After new compiling, the values should be positive. | |

| − | + | Attention, with per.resultl and per.resultr, the sign of the amplitude is displayed as actually received, regardless of the settings in CONF_LEFT_COIL_INVERSE and CONF_RIGHT_COIL_INVERSE. | |

| − | + | It may be that per.resultl provides a positive amplitude and per.resultr a negative amplitude inside the perimeter. That's OK, since it depends on the connection of the coils. Conversion with CONF_LEFT_COIL_INVERSE / CONF_RIGHT_COIL_INVERSE takes place later in the software. | |

| − | + | It is important to configure CONF_LEFT_COIL_INVERSE and CONF_RIGHT_COIL_INVERSE so that per.show displays positive amplitudes within the perimeter. | |

| − | == | + | ==Configure Bluetooth== |

| − | + | If the module has already been configured with the original Ardumower software, can CONF_BT_SERIAL_SPEED=19200 be set. | |

| − | #define CONF_BT_SERIAL_SPEED 19200 | + | #define CONF_BT_SERIAL_SPEED 19200 |

| − | + | (The perimeter outputs are extremely large.) It may be that the software faltered at this transfer rate when viewing perimeter data over BT at that baud rate.) | |

| − | ( | + | This would be the configuration then done. |

| − | + | ||

| − | + | Since there are sometimes problems with the configuration of BT modules, I suggest to reprogram a working BT module only if you have another working BT module in reserve. | |

| − | + | For the configuration of the BT the original Ardumower routine is used. However, the baud rate is set to 115200. | |

| − | + | Therefore, you can use the tips used for troubleshooting in the forum. | |

| − | |||

| − | |||

| − | |||

| − | + | Lets start: | |

| + | De-energize the PCB (also disconnect USB from the DUE). Press and hold button on BT module. Turn on the board. | ||

| + | The BT module should now flash every 2 seconds. | ||

| − | + | Release the button. Reconnect the USB to the DUE. The BT module should still be flashing every 2 seconds. | |

| − | + | ||

| − | + | Now try bt.show first, to see if the BT module is found: | |

| + | bt.show | ||

| + | If found successfully put in the command: | ||

bt.set | bt.set | ||

| − | + | The BT module will now be configured. | |

| − | == | + | ==Configure Arduino Centrale == |

| − | + | The software runs on an Android mobile phone or tablet. | |

| − | Arduino | + | Arduino Centrale can be downloaded from the Play Store. Another software that works is Serial Bluetooth Terminal. |

| − | In Arduino | + | In Arduino Centrale, the top right menu (three points) can be opened. Call Settings there. |

| − | + | Then open the button layout Configuration. Here you can set which buttons are displayed. | |

| − | + | Only the following should be selected: | |

Show Control Button | Show Control Button | ||

Show Standard Button set 1 | Show Standard Button set 1 | ||

| Zeile 496: | Zeile 488: | ||

Show Standard Button set 3 | Show Standard Button set 3 | ||

| − | + | Go back and open Serial Terminal Settings | |

| − | Terminal View Character Limit | + | Set Terminal View Character Limit to 10000 |

| − | + | Go back and select Line Ending for Commands | |

| − | + | Select CR | |

| − | + | Go back and select Line Ending for Incoming Data | |

| − | + | Select NL | |

| − | + | Then first go out completely from the menu. | |

| − | + | First, the BT module must now be paired to work with the mobile phone. | |

| − | + | That means on the phone enable BT. | |

| − | + | Then go to the BT menu on the phone and look for new devices. | |

| − | + | There should then appear a new device. Select this device and pair. | |

| − | + | There is a password query which is 1234 or 0000 | |

| − | + | Thereafter, the module is included in the device list | |

| − | + | Now in the menu of Arduino Centrale go to connect to device and click the BT of the mower. | |

| − | + | If everything was successful, BT connect should be displayed at the top right. | |

| − | + | At the command line, type H and Send. Then the help should be displayed.n. | |

| − | In Arduino | + | In Arduino Centrale commands can be stored under the menu item Standard Button Setup. |

| − | + | Currently I have deposited the following commands with me: | |

Button 1 Text: Manual Command: M | Button 1 Text: Manual Command: M | ||

Button 2 Text: Auto Command: A | Button 2 Text: Auto Command: A | ||

| Zeile 528: | Zeile 520: | ||

Button 6 Text: per Command: per.show | Button 6 Text: per Command: per.show | ||

Button 7 Text: mowense Command: mot.curm | Button 7 Text: mowense Command: mot.curm | ||

| − | Button 8 Text: bat Command: bat | + | Button 8 Text: bat Command: bat.show |

Button 9 Text: charge Command: charge.show | Button 9 Text: charge Command: charge.show | ||

| − | + | These commands can be customized as needed. | |

| − | == | + | == First test drive == |

| − | + | For safety reasons, switch off the mowmotor in config.h for the first test. | |

#define CONF_DISABLE_MOW_MOTOR true | #define CONF_DISABLE_MOW_MOTOR true | ||

| − | + | Then recompile and upload software. | |

| − | + | Attention, there are still no bumpers active! That the area inside the perimeter must be free. | |

| − | + | Disconnect the USB cable and connect to Arduino Centrale. | |

| − | |||

| − | |||

| − | + | Put the robot inside the perimeter loop. | |

| + | Check the perimeter signal again with per.show. Disable perimeter output with h or per.show | ||

| − | + | A enter for auto mode to start the mowing. | |

| − | M | + | It may take 5 seconds for something to happen. The robot first drives up the mowmotor. Since this one is turned off, it may look like it does not happen. |

| + | |||

| + | M enter for manual mode to stop the robot. | ||

=TUNE UP = | =TUNE UP = | ||

| − | == | + | == Configure the bumpers on the bumper connectors == |

| − | + | The original Ardumower chassis does not provide a standard solution for bumpers. Since most users create their own solutions here, the firmware has some options to configure the bumper service for their own needs. | |

| − | + | To enable the bumper, the following line must be configured in config.h: | |

| + | #define CONF_DISABLE_BUMPER_SERVICE false | ||

| − | + | To test bumpers, you can use the bumper.show command. The bumper service then plays its activity on the console or mobile phone, depending on where that command was sent from. | |

| + | bumper.show | ||

| − | |||

| − | + | The bumper pins are configured by default as inputs with pullup resistor. This means, the input is high by default as long as the pin is not connected to GND by a switch for example. | |

| + | The bumper service can be configured with following parameters in config.h: | ||

| − | |||

| − | + | Using the left or/and right bumper | |

| − | + | #define CONF_USE_LEFT_BUMPER true // left bumper is used | |

| + | #define CONF_USE_RIGHT_BUMPER true // right bumper is used | ||

| + | Determine if the bumper is active if the pin is connected to GND: | ||

| − | + | #define CONF_LEFT_BUMPER_LOW_ACTIVE true // left bumper is activated when pin is low | |

| − | #define | + | #define CONF_RIGHT_BUMPER_LOW_ACTIVE true // right bumper is activated when pin is low |

| − | |||

| − | |||

| + | If one uses a left and a right bumper, there is still the possibility to configure that the direction of rotation is determined by the activated bumper after driving back. That means, that when the left bumper is pressed, the robot then turns right after driving back. | ||

| − | + | #define CONF_ESCAPEDIR_DEPENDING_ON_BUMPER false // if set to true, the robot rotates in the opposite direction of the activated bumper. If false, the escape direction is random. | |

| − | + | // only set to true if you use a bumper for left and a bumper for right. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | The bumper pins are configured by default as inputs with pullup resistor in hardware.cpp: | |

| − | + | ||

| − | + | DigitalIn diBumperL(pinBumperLeft, true); | |

| − | + | DigitalIn diBumperR(pinBumperRight, true); | |

| − | + | This means the input is high by default if the pin is not pulled to GND. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | |||

| − | + | ''If you want to switch off the pull-up resistors, the lines must be changed as follows'' | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ''DigitalIn diBumperL(pinBumperLeft, false);'' | |

| + | |||

| + | ''DigitalIn diBumperR(pinBumperRight, false);'' | ||

==Charge Service== | ==Charge Service== | ||

| − | + | The charge ervice provides the BHT with the charge voltage and the charge current. It contains functions for switching the charger relay on / off. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Annotation: | |

| + | If the Mower is switched off (battery not connected) and then a charging voltage is connected to P42 Charger, | ||

| + | the board is directly supplied with voltage via D73. The problem is that the capacitors on the board have no voltage and supply a short circuit when connected. Then a 1.6A fuse will break through in EF1. | ||

| + | Therefore, EF1 should be 5A. | ||

| + | I've removed the D73 from my board, because I think it's only reasonable if the battery is so empty that the board and Relay no longer works with the battery. If this really | ||

| + | happens, I will charge the battery directly with the charger. This should be happen only in case of an error and should not be the rule (but I would not persuade anyone to do this too). | ||

| + | Furthermore, the D73 has a different potential on the back, as the diodes are soldered behind this. Since it makes sense to separate them with hot glue, not that they come together. | ||

| − | + | [[The following describes how to load the robot.]] | |

| − | + | '''Independent driving in the charging station''' | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | When the robot moves into the charging station, the charging relay is switched off. At this time, only the voltage of the charging station is at the contacts. | |

| + | If the robot has detected this, it stops, waits two seconds and checks the charging voltage again. If this is OK, it moves 3cm forward, 3cm backwards and again 2cm forward. | ||

| + | This serves to optimize the connection to the charging contacts (which are currently designed as sliding contacts). Then the relay is switched on and the charging voltage checked again. | ||

| + | (This behavior can easily be reprogrammed in the BHT.) The relay remains energized and thus the battery is connected to the charger until the robot is commanded to go to an area or the robot is switched to manual mode or switched to auto mode. | ||

| − | + | '''Use without charging station''' | |

| − | + | ||

| − | ''' | + | To load the robot it should be in manual mode (enter command M). Then you can use charge.relay,1 to switch on the relay and with charge.relay,0 to switch off the relay. The relay automatically turns off when the Auto mode is activated. '''The relay only switches on if the charging voltage is applied to the charging contacts!'''. |

| + | Another possibility is to connect the charging contacts when switched off and then turn on the robot. The robot then goes into auto mode and turns on the Behavior Charging Station. He now thinks he is in the charging station. | ||

| − | + | '''Put in the charging station''' | |

| + | Here, put the robot in the switched off state in the charging station, so that the charging contacts have contact. Then turn it on. The robot then enters the charging mode in the Behavior Charging Station. He now thinks he is in the charging station, turns on the relay and charges. | ||

| − | + | ||

| + | To enable the charging service, set the config.h CONF_DISABLE_CHARGE_SERVICE to false and re-install the software. | ||

#define CONF_DISABLE_CHARGE_SERVICE false | #define CONF_DISABLE_CHARGE_SERVICE false | ||

| − | [[ | + | [[Manual testing:]] |

| − | + | Enter the command: | |

charge.show | charge.show | ||

| − | + | This continuously displays the voltages and currents. Currently everything should be displayed with 0. | |

| − | + | Connect charger to P42 or charging contacts. | |

| − | + | Now you should see the Charge Voltage (CV).. | |

| − | + | Enable relay: | |

charge.relay,1 | charge.relay,1 | ||

| − | + | Now a current flows from the charger to the battery and a charge current is displayed (CC). | |

| − | + | Disable relay: | |

charge.relay,0 | charge.relay,0 | ||

| − | [[ | + | [[Testing in the off state via the console:]] |

| − | + | Turn on the robot and connect USB. Wait until software has started up. | |

| − | + | Connect charging contacts. | |

| − | + | Open the serial console. The DUE restarts. The relay should be energized and the console output at boot should show "Charging station detected". | |

| − | + | The robot has now switched to the Chargingbehaviour. | |

| − | M | + | Enter M to return to manual mode and switch off the relay. |

==Watchdog== | ==Watchdog== | ||

| − | + | The watchdog is solely for safety. | |

| − | + | If the software hangs, the watchdog should prevent the robot from running unchecked. | |

| − | + | The watchdog is hardware implemented in the DUE. It is activated in the config.h with: | |

#define CONF_ENABLEWATCHDOG true | #define CONF_ENABLEWATCHDOG true | ||

| − | |||

| − | |||

| − | |||

| − | + | Each time the loop is traversed, the watchdog will be reseted with the function call watchdogReset ();. | |

| − | + | If watchdogReset (); is not called within 3 seconds (because the software hangs somewhere), the DUE is restarted, stopped the engines and the software goes into manual mode. | |

| − | + | ||

| + | Annotation: | ||

| + | Since the variables of the firmware are reinitialized during the reboot, it is difficult to find out what the cause of the error is. | ||

| + | The Mower simply stops, and one wonders when opening the BT connection, that everything is fine and no error is issued - except that the software is in manual mode. | ||

| − | == | + | == Undervoltage Shutdown == |

| − | + | The undervoltage shutdown is used to prevent the battery from falling below a certain voltage and then deeply discharged. The implementation of the undervoltage shutdown is implemented in the battery service. | |

| − | + | Prerequisite is, that the jumper 8 UV shutdown on PCB 1.3 is set to Auto. If you then put voltage on the board, this gets no electricity first. Therefore, when switching on the voltage, the UV shutdown must be bridged with the P20 button. Then the PCB1.3 gets voltage. This button should be held for 4 seconds. Then the software takes control of the UV shutdown. The P20 button must then be open again, otherwise the software can not switch off the voltage. | |

| − | In | + | In config.h the threshold is set at which the voltage is switched off |

#define CONF_VOLTAGE_SWITCHOFF_BS 21.7f | #define CONF_VOLTAGE_SWITCHOFF_BS 21.7f | ||

| − | + | If the battery voltage falls below this voltage for one minute, the voltage to PCB1.3 and the motors will be cut off. | |

| − | + | The entire PCB1.3 is then dark. | |

| − | + | If you want to bridge the undervoltage cut-off, you can set jumper 8 to permanent-on or bypass P20. I have an on / off switch connected to the P20, so that I can bridge this for testing purposes. The jumper 8 is still on auto. | |

==I2C Bus== | ==I2C Bus== | ||

| − | + | The I2C bus can be scanned with the command i2c.scan. All found addresses will be displayed. | |

i2c.scan | i2c.scan | ||

| − | + | The addresses of the RTC module and the EEPROM can be adjusted in the hardware.cpp. Currently the following default addresses are configured: | |

byte DS1307_ADDRESS = B1101000; | byte DS1307_ADDRESS = B1101000; | ||

| Zeile 751: | Zeile 697: | ||

==RTC== | ==RTC== | ||

| − | + | The RTC module is currently not used. It is intended to use this later for a time mowing start. | |

| − | + | However, the RTC module can already be programmed and tested. | |

| − | + | The RTC module is activated with the following line in the config.h: | |

define CONF_DISABLE_EEPROM_SERVICE false | define CONF_DISABLE_EEPROM_SERVICE false | ||

| − | + | The following commands are available: | |

rtc.show //show rtc values every rtc read (10sec) | rtc.show //show rtc values every rtc read (10sec) | ||

rtc.config //show rtc service config | rtc.config //show rtc service config | ||

| Zeile 765: | Zeile 711: | ||

==EEPROM== | ==EEPROM== | ||

| − | + | The EEPROM is used on the RTC. Currently it is used to store statistics. The following statistics are stored: total mowing time, total distance traveled, total number of rotations, number of loading operations. | |

| − | + | The use of the EEPROM is switched on with the following line in the config.h: | |

#define CONF_DISABLE_EEPROM_SERVICE false | #define CONF_DISABLE_EEPROM_SERVICE false | ||

| − | + | The following commands are available for the EEPROM: | |

eep.config //show EEPROM service config | eep.config //show EEPROM service config | ||

| Zeile 782: | Zeile 728: | ||

eep.erase //erase the eeprom | eep.erase //erase the eeprom | ||

| − | + | To test the EEPROM e.g. enter the following command: | |

eep.set.f,10,7.3 | eep.set.f,10,7.3 | ||

| − | + | This writes the float value 7.3 to the addresses 10, 11, 12, 13 in the EEPROM. | |

| − | + | With the command | |

eep.f,10 | eep.f,10 | ||

| − | + | the value can then be read out again. | |

| − | + | The command eep.erase deletes the first 3 pages of the EEPROM. The other pages are currently not deleted because they are not used. | |

eep.erase | eep.erase | ||

| − | + | It makes sense to erase the EEPROM after the enable the service so that the memory cells are initialized. | |

| − | == | + | == Slow down the speed at the perimeter == |

| − | + | The Mower drives at a speed of 1200m / s. In order to make the deceleration a bit gentler when driving over the perimeter, the robot reduces the speed just before the perimeter (about 20 cm). | |

| − | + | The following constants in the config.h affect recognition near the perimeter: | |

#define CONF_NEAR_PER_UPPER_THRESHOLD 80.0L // Threshold of one coil where Perimetersignal is detected as near perimeter | #define CONF_NEAR_PER_UPPER_THRESHOLD 80.0L // Threshold of one coil where Perimetersignal is detected as near perimeter | ||

#define CONF_NEAR_PER_LOWER_THRESHOLD 70.0L // Threshold of the other coil where Perimetersignal is detected as near perimeter | #define CONF_NEAR_PER_LOWER_THRESHOLD 70.0L // Threshold of the other coil where Perimetersignal is detected as near perimeter | ||

| − | + | To determine if the robot is close to the perimeter, the amplitude of the left and right coils are evaluated. For this purpose, the firmware determines the current maximum amplitude over the entire travel time of the Mower. Now, when the left coil reaches an amplitude of 80% (CONF_NEAR_PER_UPPER_THRESHOLD) or higher of the maximum value and the right coil reaches above 70% (CONF_NEAR_PER_LOWER_THRESHOLD) or higher of the maximum value, it is assumed that the robot is close to the perimeter. The same applies if the right coil reaches 80% and the left 70%. | |

| − | + | These values depend on the kind of coil used and on the signal strength of the transmitter and therefore may need to be readjusted. | |

| − | + | To adjust this, enter the command per.show while the Mower is driving. | |

per.show | per.show | ||

| − | + | If the mower then runs over the perimeter wire enter the same command or press h. Then scroll back in the display and look at the values. | |

| − | + | Example: | |

!03, ML: 305 MR: 331 magMax:332 magMedL%: 73 magMedR%: 87 | !03, ML: 305 MR: 331 magMax:332 magMedL%: 73 magMedR%: 87 | ||

| − | + | The values magMedL%: 73 magMedR%: 87 indicate here the measured percentage of the coils 20cm before the perimeter wire. Use this percentage as starting point to set CONF_NEAR_PER_UPPER_THRESHOLD and CONF_NEAR_PER_LOWER_THRESHOLD. Several tests should be carried out for the determination. Better to slow down a little earlier than to slow down too late. The difference between UPPER and LOWER has been introduced because the coils do not have always the same value, e.g. when the Mower is running obliquely or almost parallel to the perimeter. | |

| − | + | It may be that magMedL% and magMedR% show more than 100%. This is based on the type of magMax determination and is OK. | |

| − | + | The calculation is stored in the function '' 'bool TPerimeterThread :: isNearPerimeter ()' '' in the file perimeter.cpp. | |

| − | == | + | == Set mower motor current == |

| − | + | It should be noted that the outputs of the mowing motor driver on PCB1.3 have been interconnected. | |

| − | + | With a PWM of 255 at the mower motor almost no current is measured on my board. I have then remeasured the value with a multimeter. I measure at M2 FB at full speed and free-wheel only 0.04V. Correct value would be about 0.22V because the engine pulls here 0.41A. On M1 M1 I measure a voltage of 0.007V. It seems that the current measurement is no longer correct due to the parallel connection. One might think that this should be halved. But it is not like that. | |

| − | + | An interconnection of the two MC33926 is not recommended by the manufacturer and seems to provide an incorrect current measurement. | |

https://www.nxp.com/docs/en/application-note/AN4833.pdf | https://www.nxp.com/docs/en/application-note/AN4833.pdf | ||

| − | + | Quote:"If two independent H-bridges are used (separate MC33926 or similar), the load sharing may not be quite as even, | |

resulting in a reduction in maximum drive capability. This configuration will latch any fault until the EN pin is toggled." | resulting in a reduction in maximum drive capability. This configuration will latch any fault until the EN pin is toggled." | ||

| − | |||

| − | + | I have then disconnected from the Mowmotor driver pins M1 OUT1 and M1 OUT2 (bent and guided next to the socket connector, so that they have no contact). Now the current measurement works properly, but under 1A this is not really accurate. Only from 1A the value is reliable. | |

| + | |||

| + | Forum Posts: | ||

https://www.ardumower.de/index.php/de/forum/ardumower-1-3-mainboard/1461-pcb1-3-motorstrom-wird-vermutlich-falsch-gemessen#13904 | https://www.ardumower.de/index.php/de/forum/ardumower-1-3-mainboard/1461-pcb1-3-motorstrom-wird-vermutlich-falsch-gemessen#13904 | ||

| − | + | If M1 OUT1 and M1 OUT2 are not disconnected, the measured and displayed current too low. | |

| − | + | Therefore, the scale value for the correct current measurement must be adjusted in the setup function of the class TMowMotorSensor in the file mowmotorSensor.h. | |

| − | + | The scale factor should be set at currents around 1A or more. Therefore he mower disc must be loaded with resitance when measuring the current with the multimeter. | |

| − | + | If M1 OUT1 and M1 OUT2 are disconnected, the factor whih is set by default and find out by measuring is probably reasonably correct. However, this can only be checked by measuring current levels of 1A. | |

| − | + | The measured current and wattage are displayed with the command: | |

| − | mot.curm | + | mot.curm |

| − | + | ||

| − | == | + | == Slow down when mower engine is loaded == |

| − | + | When the mower motor is loaded, the mower slows down. | |

| − | + | From which wattage of the mower motor the mower is slowed down, can be configured in the config.h with the parameter | |

#define CONF_MOW_MOT_UNDER_LOAD 30.0f | #define CONF_MOW_MOT_UNDER_LOAD 30.0f | ||

| − | + | If the mower needs more than 30W, the speed will slow down. | |

| − | + | The current watts number when mowing can be displayed with the command: | |

mot.curm | mot.curm | ||

| − | + | Thereafter, the value can be set at its discretion. | |

| − | + | Attention, the motor drivers deliver an accurate current measurement only from 1A on (according to data sheet 0.5A). | |

| − | + | That Values where the current is displayed under 1A are inaccurate and should not be used. | |

| − | + | The accuracy is according to data sheet at a current of over 0.5A + -20%. | |

| − | + | The speed setting code is in the class class TCruisePerimeterNear: public Node in the bCruise.h file. | |

| − | + | Furthermore, it must be taken into account that the outputs of the mower motor driver have been interconnected. This is not recommended by the manufacturer and provides incorrect current measurement. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

==Perimeter Tracking== | ==Perimeter Tracking== | ||

| − | + | Here, the perimeter tracking algorithm is explained, with the aim of providing enough information to be optimized by the user on its chassis. The choice fell on this algorithm, since it is independent of the perimeter amplitude. Furthermore, the algorithm is extremely stable and is to be diverted from its intention to follow the perimeter. [https://www.youtube.com/watch?v=RdufyzkYSPU '' 'Video Example' ''] | |

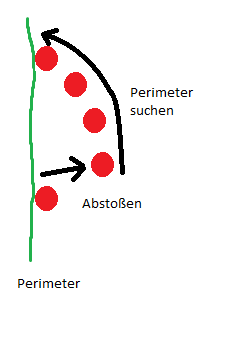

| − | + | The perimeter tracking algorithm uses a one bounce algorithm. The algorithm move off counterclockwise on the perimeter. The right outer coil bounce always against the perimeter from the outside. When it hits the perimeter, the coil is first repelled by the perimeter. Thereafter, the coil moves in an arc towards the perimeter. [https://www.youtube.com/watch?v=Y3wxURV0qtw '' 'Video Example' ''] | |

[[Datei:OneBounce.png]] | [[Datei:OneBounce.png]] | ||

| − | + | The algorithm is in the file: bGotoAreaX.h class: TlineFollow implemented. | |

| − | + | The following diagram shows the "if" queries in a different chronological order for a better explanation than they actually are in the program code. Therefore, do not be confused when looking at the program code. | |

| − | + | Procedure: | |

| − | + | The right coil is always outside the perimeter. | |

| − | + | If this exceeds the perimeter inwards, an aggressive rotation is first executed clockwise with: | |

bb.motor.L->setSpeed((bb.cruiseSpeed + 5)); | bb.motor.L->setSpeed((bb.cruiseSpeed + 5)); | ||

bb.motor.R->setSpeed((bb.cruiseSpeed - 20)); | bb.motor.R->setSpeed((bb.cruiseSpeed - 20)); | ||

| − | + | Should the coil not be outside after 1 second, the rotation becomes more aggressive: | |

if ((millis() - lastTransitionTime) > 1000) { // If more than 1sec inside rotate aggressive | if ((millis() - lastTransitionTime) > 1000) { // If more than 1sec inside rotate aggressive | ||

bb.motor.L->setSpeed((bb.cruiseSpeed + 10)); | bb.motor.L->setSpeed((bb.cruiseSpeed + 10)); | ||

| Zeile 947: | Zeile 838: | ||

} | } | ||

| − | + | If the coil is not outside after 1.5 seconds, the mower will turn | |

if ((millis() - lastTransitionTime) > 1800) { | if ((millis() - lastTransitionTime) > 1800) { | ||

bb.cruiseSpeed = 25; | bb.cruiseSpeed = 25; | ||

| Zeile 955: | Zeile 846: | ||

} | } | ||

| − | + | When the coil is now turned out, the robot moves a shallow counter clockwise curve until it reaches the perimeter. | |

| − | + | For the calculation of the curve, an integral is used, which can be controlled by the factor Ki. | |

| − | ( | + | (Note: The integral is set to 0 as soon as the coil crosses the perimeter.) |

| − | integral = integral + (Ki*error); // | + | integral = integral + (Ki*error); // the value error is a constant and has the value -1 if the coil is outside the perimeter. |

double Output = integral; | double Output = integral; | ||

| − | + | The move of the curve is then carried out as follows: As the integral increases, the curve becomes smaller as the integral becomes larger. | |

| − | bb.motor.L->setSpeed((bb.cruiseSpeed + Output)); // | + | bb.motor.L->setSpeed((bb.cruiseSpeed + Output)); // note: output is negative |

bb.motor.R->setSpeed((bb.cruiseSpeed)); | bb.motor.R->setSpeed((bb.cruiseSpeed)); | ||

| − | + | If the perimeter is not exceeded after 1 second, the curve is driven more aggressively; | |

if ((millis() - lastTransitionTime) > 1000) { // If more than 2sec Outside rotate aggressive | if ((millis() - lastTransitionTime) > 1000) { // If more than 2sec Outside rotate aggressive | ||

bb.motor.L->setSpeed((bb.cruiseSpeed + Output)); | bb.motor.L->setSpeed((bb.cruiseSpeed + Output)); | ||

bb.motor.R->setSpeed((bb.cruiseSpeed +5)); | bb.motor.R->setSpeed((bb.cruiseSpeed +5)); | ||

} | } | ||

| − | + | If after 1.5 seconds the perimeter was not exceeded, the curve is driven even more aggressive: | |

if ((millis() - lastTransitionTime) > 1500) { // If more than 2.8sec Outside rotate more aggressive | if ((millis() - lastTransitionTime) > 1500) { // If more than 2.8sec Outside rotate more aggressive | ||

bb.motor.L->setSpeed((bb.cruiseSpeed + Output)); | bb.motor.L->setSpeed((bb.cruiseSpeed + Output)); | ||

bb.motor.R->setSpeed((bb.cruiseSpeed +10)); | bb.motor.R->setSpeed((bb.cruiseSpeed +10)); | ||

} | } | ||

| − | + | If after 2 seconds the perimeter has not been exceeded, the following is rotated: | |

if ((millis() - lastTransitionTime) > 1500) { // If more than 2.8sec Outside rotate more aggressive | if ((millis() - lastTransitionTime) > 1500) { // If more than 2.8sec Outside rotate more aggressive | ||

bb.motor.L->setSpeed((bb.cruiseSpeed + Output)); | bb.motor.L->setSpeed((bb.cruiseSpeed + Output)); | ||

| Zeile 989: | Zeile 880: | ||

| − | + | If the left coil is outside the perimeter, immediately counter clockwise is turned: | |

if (bb.perimeterSensoren.isLeftOutside() == true) { | if (bb.perimeterSensoren.isLeftOutside() == true) { | ||

bb.cruiseSpeed = 25; | bb.cruiseSpeed = 25; | ||

| Zeile 999: | Zeile 890: | ||

| − | + | To set the algorithm, the first thing you should try to do is drive straight. Here is the first turn out to configure and Ki for the curve to drive in. | |

| − | + | Testing the algorithm: | |

| − | + | Place the robot on the perimeter so that the right coil is on the outside and the left coil on the inside. Start the perimeter tracking with the command. | |

tpt //test perimeter tracking to dock. Mower stands on perimeter | tpt //test perimeter tracking to dock. Mower stands on perimeter | ||

| − | + | ||

| − | + | The command | |

M | M | ||

| − | + | stops the test. | |

| + | |||

| + | With the command | ||

| + | set.lfki, 1.1 | ||

| + | the Ki value can be set during testing. If satisfactorily determined, the value must be assigned in the TlineFollow class in the constructor. | ||

| + | |||

| + | When the drive wheels are rear, the distance to the coils is greater and the coils can be located off center. The original Ardumower chassis has front drive wheels. Here, the right coil must be placed close to the center, otherwise the rotation is too asymmetrical. Due to the short distance, the bounce interval of 1 sec is probably to be shortened, so that on a straight line probably all 0.3sec must be bounced. (Currently not tested) | ||

| − | + | == Fast return == | |

| − | + | On the way back to the charging station, it may happen that the Mower drives at one point onto the perimeter so that it has to drive the entire perimeter wire to the charging station. To shorten this way, there is the fast return. | |

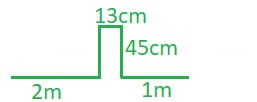

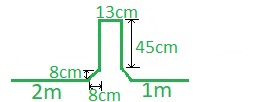

| − | + | The user has to lay the perimeter cable so that it results in a square. This quadrilateral is then recognized by the robot during perimeter tracking. When he recognizes the square, he turns 90 degrees from the perimeter into the interior, and moves to the other side of the lawn. When he discovers the perimeter cable, he picks up the perimeter tracking again. | |

| − | + | To enable the fast return you have to set following option in config.h. | |

| + | #define CONF_DISABLE_FAST_RETURN false | ||

| − | + | For the square, the following dimension has been found to be favorable. However, it depends on the dimensions of the Mower. The Mower should come while tracking in the turning mode. Turn at the first left curve. Then turn at the next right curve. Then drive left curve. [Video:https://youtu.be/ipdVJzQn5Tc] | |

| − | + | ||

| − | + | ||

| − | |||

| − | + | The square can be laid in two ways. Once with corners and once with flattened corners. The flattened corners are there for the mower to better recognize at the corner in which direction it should turn away from the perimeter when it is almost parallel to the perimeter. As a result, the perimeter nearest coil is the first outside and it turns away from the perimeter rather than toward the perimeter. This is necessary if there is a bed behind the perimeter into which the mower could turn. | |

[[Datei:ViereckSchnelleRückkehr.JPG]] | [[Datei:ViereckSchnelleRückkehr.JPG]] | ||

| Zeile 1.028: | Zeile 923: | ||

<gallery> | <gallery> | ||

| − | File:Raindancer FastReturn.png | | + | File:Raindancer FastReturn.png | Example, how I lay down my squares |

</gallery> | </gallery> | ||

| − | + | The detection depends on the position of the coils and the distance between the coils and the drive wheels. | |

| − | + | The implemetation is in the file: bPerimeterTracking.h Class: class TfindTriangle: public Node | |

| − | + | Detection is based on the rotated angle. It was implemented with a state machine. | |

| − | + | The procedure of the statmachine and the calculated angles can be displayed with the command: | |

bht.tri | bht.tri | ||

| − | + | The corresponding angles and maximum distances must then be adapted in the code in class: class TfindTriangle. | |

| − | + | Below Ishow slightly thinned class to get a better overview. The lines errorHandler.setInfoNoLog (..) are the output if the command bht.tri has been activated. These were listed here to better interpret the issue. | |

virtual NodeStatus onUpdate(Blackboard& bb) { | virtual NodeStatus onUpdate(Blackboard& bb) { | ||

... | ... | ||

| − | + | The driven angle is determined every 500ms before the case statement. | |

//============================================ | //============================================ | ||

// Calculate driven angle every 500ms. | // Calculate driven angle every 500ms. | ||

| Zeile 1.059: | Zeile 954: | ||

} | } | ||

} | } | ||

| − | + | Query the States | |

// Check for left curve / right curve / second left curve | // Check for left curve / right curve / second left curve | ||

switch (state) | switch (state) | ||

{ | { | ||

| − | + | In case 0, a left turn is searched. A negative angle means a left curve/turn. If the angle is e.g. <-25 degrees, a curve was found and it will branched into case 1. | |

case 0: // search for left curve | case 0: // search for left curve | ||

if (angle < -25) { | if (angle < -25) { | ||

| Zeile 1.076: | Zeile 971: | ||

break; | break; | ||

| − | In case 1 | + | In case 1, it is constantly checked whether a certain distance has been exceeded after the left turn. In the example 55cm. If so, that is too far and it jumps back into the case 0, since it can not be that the first way is so long. If an angle> 50 has been found within the distance of 55cm, the case 2 is jumped. A positive angle means a right turn. |

case 1: // search for right turn | case 1: // search for right turn | ||

distance = bb.motor.getDistanceInCMForTriangle(); | distance = bb.motor.getDistanceInCMForTriangle(); | ||

| Zeile 1.095: | Zeile 990: | ||

break; | break; | ||

| − | In case 2 | + | In case 2, the distance traveled after the right angle is checked first again. As long as the distance of 50 cm has not been exceeded, a left turn is checked. If the angle is <-25 degrees, a curve was detected and jumped into state 3. |

case 2: // search for second left curve | case 2: // search for second left curve | ||

distance = bb.motor.getDistanceInCMForTriangle(); | distance = bb.motor.getDistanceInCMForTriangle(); | ||

| Zeile 1.114: | Zeile 1.009: | ||

break; | break; | ||

| − | Case 3 | + | Case 3 returns BH_SUCCESS to the BHT and the mower drives to the other side of the lawn. |

case 3: | case 3: | ||

if (flagShowFindTriangleStates) { | if (flagShowFindTriangleStates) { | ||

| Zeile 1.129: | Zeile 1.024: | ||

| − | + | Testing the Algorithm: Place the robot on the perimeter so that the left coil is on the outside and the right coil is inside. Start the perimeter tracking with the command. | |

tpt //test perimeter tracking to dock. Mower stands on perimeter | tpt //test perimeter tracking to dock. Mower stands on perimeter | ||

| − | |||

| − | + | ||

| + | Start the output of the quadrilateral detection with the command. | ||

bht.tri | bht.tri | ||

| − | + | (tri stands for triangle, since previously a triangle was used for detection) | |

| − | == | + | == Mowing zones between adjacent surfaces == |

| − | + | Mowing zones can be set up between adjacent surfaces that have a direct connection. For this, the perimeter cable between the surfaces is laid at a distance of about 13cm. A gap of about 30cm or less is left to the opposite perimeter cable. This reduces the likelihood that the robot will move to the other area. | |

| − | + | See image: | |

<gallery> | <gallery> | ||

File:RaindancerGroundAreas.png | Beispiel, Mähzonenabgrenzung | File:RaindancerGroundAreas.png | Beispiel, Mähzonenabgrenzung | ||

| Zeile 1.146: | Zeile 1.041: | ||

</gallery> | </gallery> | ||

| − | ''( | + | ''(In the picture above, it is not normally necessary to set up mowing zones, as the robot covers relatively well all areas of the lawn by the algorithm.)'' |

| − | + | The distance of the area delineation cable to the opposite perimeter cable (here 30cm distance) can be optimized by tests. The distance depends on the functionality of the perimeter tracking. Firstly, the position of the left coil when tracking the overlying cable, as well as the tracking of the area delineation cable itself. | |

| − | + | Since the robot travels with the coils about 20 cm over the cable by default, it may be that it stops with the coils within the next range. | |

| − | + | ||

| − | + | Approaching an area from the charging station is done with the command: | |

| − | + | area,x // where x is the path to be traveled in m. | |

| − | + | If the specified distance x has been covered at the perimeter, the Mower starts mowing. | |

| − | + | The distance traveled on the perimeter can be displayed or measured with the command. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

show.distance | show.distance | ||

| − | |||

| − | |||

| − | + | Attention: It is important to remember exactly where the mower zone cables are located in case the grass is scarred. | |

| − | + | ||

| − | + | ||

| − | + | == Laying the Perimeter Cable at Corners == | |

| + | The Mower determines in which direction he turns on the perimter on the basis of the coil that was pulled out first. Therefore it is important not to lay the corners at 90 degrees. | ||

| + | For example, if the Mower, with the right spool, moves close parallel to the perimeter and then drives out at the corner, the right spool should also be the first to leave the perimeter. | ||

| + | |||

| + | The following pictures show three examples of how corners should be moved.. | ||

<gallery> | <gallery> | ||

| Zeile 1.179: | Zeile 1.069: | ||

</gallery> | </gallery> | ||

| − | = | + | ==Temperature Sensor== |

| − | + | The temperature sensors DHT11 / DHT21 / DHT22 / AM2301 are supported. Currently only the sensor DHT22 was tested. | |

| + | The temperature sensor is connected to the designated port of the PCB1.3. | ||

| − | + | In config.h the used temperature sensor must be configured: | |

| + | #define DHTTYPE DHT22 | ||

| + | |||

| + | To enable the service, the following line must be configured: | ||

| + | #define CONF_DISABLE_DHT_SERVICE false // Disables temp sensor | ||

| + | |||

| + | The sensor is read out with the following command: | ||

| + | temp.show | ||

| + | In manual mode, the sensor is read out directly. Temperature, humidity and the last temperature stored in the service are displayed. | ||

| + | In auto mode, only the temperature stored in the service is displayed. The temperature is updated when the mower drives over the perimeter wire and comes to a stop and time has passed at least 20 seconds since the last measurement. | ||

| + | |||

| + | The DHT service turns off the power of the PCB1.3 when a temperature of 50 degrees has been measured twice: | ||

| + | #define CONF_OVERHEATING_TEMP 50.0f // if this temperature is measured, robot shuts down the complete power for security | ||

| + | |||

| + | ==Rain Sensor== | ||

| + | When the robot mows in AUTO mode and it starts to rain, the robot returns to the charging station. | ||

| + | The rain sensor is connected to the designated port of PCB1.3. | ||

| + | The sensitivity of the rain sensor is set on the rain sensor with the potentiometer. | ||

| + | |||

| + | To enable the service, the following line must be configured: | ||

| + | #define CONF_DISABLE_RAIN_SERVICE false // Disables rain sensor | ||

| + | |||

| + | The rain sensor is read out approx. every 1.7 seconds. | ||

| + | |||

| + | The read out can be displayed with | ||

| + | rain.show | ||

| + | |||

| + | ==Shutdown Service== | ||

| + | |||

| + | When the shutdown service is activated, it shuts off the power via the undervoltage protection. | ||

| + | If a Raspberry PI is connected to the USB port, | ||

| + | CONF_WAIT_FOR_PI_SHUTDOWN = true | ||

| + | can be set. | ||

| + | Then the software waits 50 seconds for shutdown. | ||

| + | Every second, $PwrOff and a countdown are sent to the PI so that it can shut down. | ||

| + | |||

| + | With the command: | ||

| + | poweroff | ||

| + | the shutdown can be activated via the user interface or from the PI. | ||

| + | |||

| + | The shutdown service is also used by the battery service and the temperature service to shut down. | ||

| + | Thus, the PI is informed that it should shut down if the battery voltage is too low or the temperature too high. | ||

| + | |||

| + | ==GPS Service== | ||

| + | The GPS service receives the data from the GPS module. | ||

| + | |||

| + | There are two ways to process this data. Both options can be used in parallel. | ||

| + | a) The received GPS data will be forwarded to the Raindancer Controlcenter. | ||

| + | b) The received GPS data are evaluated in the Raindancer firmware. You can then define an area on the lawn. | ||

| + | If the mower is in this area, it is assumed that the mower is inside the perimeter wire. So it is possible to bridge a weak perimeter signal on larger areas. | ||

| + | |||

| + | The GPS module is connected to the dedicated connector on PCB1.3. The GPS module periodically sends data to PCB1.3. | ||

| + | If no data is received, please read the following article. It may be that RX3 and TX3 on the PCB1.3 were wired incorrectly. | ||

| + | https://www.ardumower.de/index.php/de/forum/navigation-gps-odmetrie/1737-wait-for-gps-position-data | ||

| + | |||

| + | ===Send to the Raindancer Controlcenter=== | ||

| + | To enable the GPS service, the following must be configured:: | ||

| + | #define CONF_DISABLE_GPS false | ||

| + | |||

| + | For the first commissioning you can set the following parameters: | ||

| + | #define CONF_GPS_PASS_THROUGH true | ||

| + | #define CONF_DEACTIVATE_GPS_CALCULATION true | ||

| + | The parameter #define CONF_GPS_PASS_THROUGH tells the firmware that all received GPS data should be sent to the control center. | ||

| + | |||

| + | |||

| + | In order to get this data displayed on the console, the following command must be executed: | ||

| + | set.cco, 1 | ||

| + | Now you can see all the data sent to the control center. Including the GPS records. | ||

| + | |||

| + | With the following command you stop the output: | ||

| + | set.cco,0 | ||

| + | |||

| + | |||

| + | |||

| + | By default, the GPS module sends multiple records in a 1 second interval. These records are not all needed and generate an overhead. | ||

| + | Only the record: $GPRMC for NEO-6M and $GNRMC for NEO-M8N are needed. | ||

| + | Therefore, there is the possibility to configure the module when starting the Raindancer firmware so that it sends only the required record and this only in a 3 second cycle. | ||

| + | For this the following parameter is set: | ||

| + | #define CONF_INIT_GPS_WITH_UBLOX true | ||

| + | Thus the array const char UBLOX_INIT [] (in config.h) is sent to the GPS module during startup. To activate or deactivate you have to comment in or comment out individual lines. | ||

| + | |||

| + | |||

| + | === Enable internal calculation === | ||