Motor driver: Unterschied zwischen den Versionen

(→Wheel motors) |

(→Protector PCB) |

||

| (189 dazwischenliegende Versionen von 2 Benutzern werden nicht angezeigt) | |||

| Zeile 1: | Zeile 1: | ||

= Abstract = | = Abstract = | ||

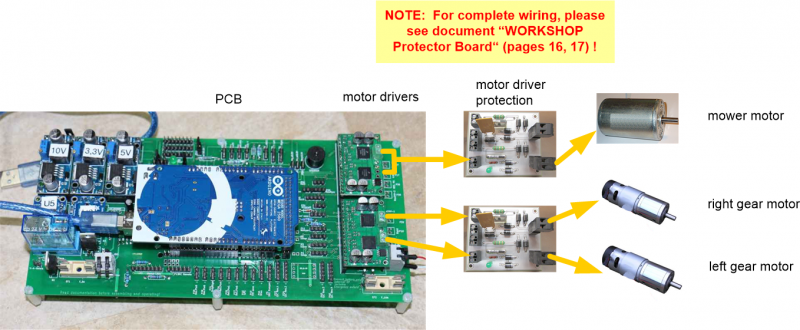

| − | Ardumower uses two different motors: | + | Ardumower uses two different types of motors (all motors can be purchased via the [https://www.marotronics.de/index.php?k=7 shop] [[File: shopping.png|link=https://www.marotronics.de/index.php?k=7]]): |

| − | * Two motors (with integrated gearing) for driving (wheel motors) | + | * Two motors (with integrated gearing) for driving (wheel motors) and with integrated encoders (for distance and speed control) |

* One motor (with high rotation speed) for mowing (mower motor) | * One motor (with high rotation speed) for mowing (mower motor) | ||

| − | To control | + | To control the motors, it requires motor drivers. In addition, the motor driver measures the motor current, and allows us to detect obstacles as motor current increases at obstacles. Ardumower uses two dual MC33926 motor drivers, so two channels for left and right motor and two dual channels (connected in parallel) for the mowing motor. |

| − | + | It is not safe to connect motors directly to the motor driver. Especially, when quickly turning motors from forward to reverse (or vice verse), high voltage spikes appear, and these could damage the motor drivers in the long run. Therefore, we developed driver protector boards that are connected between motor driver and motor. | |

| − | + | ||

| − | + | [[File:Ardumower_motordriver_overview.png|800px]] | |

| − | + | = Voltages = | |

| − | + | As in all modern systems, Ardumower uses 24V motors. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | = Motor driver assembly (dual MC33926) = | |

| + | Motor driver features: up to 3A with integrated current sensor and thermal shut-down protection | ||

| − | |||

<gallery> | <gallery> | ||

| − | File: | + | File: Ardumower_motordriver_overview.png | PCB, MC33926, protector and motors |

| + | File: Pcb_mc33926.jpg | PCB and MC33926 | ||

| + | File:Mc33926.jpg | MC33926 pinout | ||

| + | File:MC33926_schematics.jpg | MC33926 schematics | ||

</gallery> | </gallery> | ||

| − | |||

| − | * | + | * [https://www.youtube.com/watch?feature=player_embedded&v=DokrJiVzX2I Video instructions: Dual MC33926] |

| − | + | ||

| − | + | For wiring of motor drivers, protector and motors, please open manual in section Protector PCB. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | = | + | =Protector PCB= |

| − | + | [[File:warning.png]] When quickly tunring motors from forward to backward (or vice versa), high voltage spikes appear. These high voltage spikes could damage the motor driver in the long run. To eliminate high voltage spikes, it is adviced to use a [https://github.com/Ardumower/ardumower/blob/master/Dokumentation/Protector%20Board/WORKSHOP%20Protector-Board.pdf Protector board] between motor driver and motor. Two Protector PCBs are required, one for the gear motors, and one for the mowing motor. | |

| − | + | <gallery> | |

| + | File: Ardumower_motordriver_overview.png | PCB, MC33926, protector and motors | ||

| + | File:Protector_pcb2.jpg | Protector PCB | ||

| + | File:Protector_wiring.png | Protector PCB wiring | ||

| + | File:driver_hw_protection.png | Protector PCB schematics | ||

| + | </gallery> | ||

| − | + | * [https://github.com/Ardumower/ardumower/blob/master/Dokumentation/Protector%20Board/WORKSHOP%20Protector-Board.pdf Assembly manual: Protector board (required for safe-use of motor drivers!)] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| + | = Wheel motors wiring = | ||

<gallery> | <gallery> | ||

| − | File: | + | File: Ardumower_motordriver_overview.png | PCB, MC33926, protector and motors |

| + | File: ardumower_motor.jpg | Ardumower gear motor with encoder (8mm diameter, 5900 rpm motor, 0.055 Nm, gear ratio 1/212, output torque 2.45Nm, output rpm 31) | ||

| + | File: magnetic_encoder.PNG | Motor wiring | ||

| + | File: wheel_motor_diagram.png | Ardumower gear motor curve (motor only) | ||

| + | File: Ardumower_gearbox.png | Gearbox specification | ||

</gallery> | </gallery> | ||

| + | The two left and right gear motors are controlled independently (aka 'differential driving') to: | ||

| − | + | * drive the robot forward/backward | |

| − | + | * steer the robot left/right | |

| − | + | Wheel motor features: | |

| + | * A rotation speed up to 31 rpm allows to move the robot at sufficient speed (at up to meter/sec = 31rpm/60 * PI * 0.25m = 0.4m/sec using 250mm diameter wheels) | ||

| + | * A high torque (2.45Nm) guarantees that the robot can climb small hills as well (with 2 motors, 0.125 radius wheel, 31rpm = 0.4m/s, acceleration = 0.2 ( 1/2 of nominal speed) [http://www.robotshop.com/blog/en/drive-motor-sizing-tool-9698 see calculator] | ||

| + | * Integrated encoders, so it can measure the rotation speed and the distance | ||

| + | * 24V (load current ~1A) | ||

| − | + | The left gear motor is connected as follows to the protector board: | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | Motor wiring (left motor): | |

| − | + | Motor (black) ==== Protector board Motor_1_OUT(1) | |

| − | + | Motor (red) ==== Protector board Motor_1_OUT(2) | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | For right motor, use Protector board Motor_2_OUT(1,2) accordingly. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | == | + | = Wheel motors odometry wiring = |

| − | + | ||

| − | + | ||

| − | + | The Ardumower gear motors have integrated encoders. These encoders help us to compute speed and traveled distance. Here's how you connect the motor odometry wires to the PCB. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

<gallery> | <gallery> | ||

| − | File: | + | File: magnetic_encoder.PNG | Motor wiring |

| − | File: | + | File: ardumower_odometry_encoder.jpg | Encoder signal |

| − | + | ||

</gallery> | </gallery> | ||

| − | + | Motor odometry wiring (left motor): | |

| − | + | Motor (brown) ---- PCB VCC | |

| + | Motor (green) ---- PCB GND | ||

| + | Motor (blue) ---- PCB OdometryLeft (3) | ||

| + | Motor (purple) ---- PCB OdometryLeft (4) | ||

| − | + | For right motor, use PCB OdometryRight accordingly. | |

| − | + | IMPORTANT: PCB v0.5/1.2 are missing pull-up resistors! You need to add them yourself at the PCB: | |

| − | + | PCB OdometryLeft(3) --- 4.7k --- 5v | |

| − | + | PCB OdometryLeft(4) --- 4.7k --- 5v | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| + | = Mower motor wiring = | ||

<gallery> | <gallery> | ||

| − | File: | + | File: Ardumower_motordriver_overview.png | PCB, MC33926, protector and motors |

| + | File: ardumower_mower_motor.jpg | Ardumower mower motor | ||

| + | File: Mower_motor_curve.png | Ardumower mower motor curve | ||

| + | File: Mower2_start_current.png | Mower start current | ||

| + | File: Mower4_blocked_500ms_detect_5s_wait.png | Mower blocked, 500ms detection (max), waittime: 5sec (min) | ||

</gallery> | </gallery> | ||

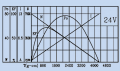

| − | + | The Ardumower mower motor features: | |

| − | + | ||

| − | The mower motor features: | + | |

* Fast enough to cut the lawn (3150 rpm) | * Fast enough to cut the lawn (3150 rpm) | ||

| − | * Enough torque (140 mNm) | + | * Enough torque (140 mNm / 46 W) |

| − | + | * Quiet mowing (you cannot hear it) | |

| − | + | * 24V, load current ~1.0A (L=2.8mH, R=1.9ohm) | |

[[File:warning.png]]'''Security note: For security reasons, always remove mower blades in your first tests!''' | [[File:warning.png]]'''Security note: For security reasons, always remove mower blades in your first tests!''' | ||

| − | |||

| − | |||

| − | |||

| − | = | + | Here's how you connect the mowing motor to the protector board: |

| + | Motor (black) ==== Protector board Motor_1_OUT(1) | ||

| + | Motor (red) ==== Protector board Motor_1_OUT(2) | ||

| − | + | = Motor decrease noise = | |

| − | + | ||

| − | + | ||

| − | + | Here's how you can decrease motor noise: | |

| − | + | ||

| − | + | <gallery> | |

| + | File:decrease_motor_noise.png | Decrease motor noise | ||

| + | </gallery> | ||

| − | + | * [https://github.com/Ardumower/ardumower/blob/master/Dokumentation/Motor%20Entstoerung/Motor%20EntstoerungREV20150531.pdf Instructions: Motor-decrease noise REV20150531] | |

| + | * [http://www.ardumower.de/media/kunena/attachments/1725/Motor-EntstoerungREV20150531.pdf (English comments)] | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

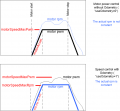

| + | = Motor controller (PID) = | ||

| + | The speed of the motors is controlled by a software PID controller. You can monitor the quality of the motor speed control via pfodApp (Plot->Motor control): | ||

<gallery> | <gallery> | ||

| − | File: | + | File:Speedcontrol.png | Motor speed settings |

| + | File: Odometry_motor_pid_controller.png | ||

</gallery> | </gallery> | ||

| − | |||

| − | |||

| − | |||

Aktuelle Version vom 22. Februar 2017, 09:45 Uhr

Inhaltsverzeichnis

Abstract

Ardumower uses two different types of motors (all motors can be purchased via the shop ![]() ):

):

- Two motors (with integrated gearing) for driving (wheel motors) and with integrated encoders (for distance and speed control)

- One motor (with high rotation speed) for mowing (mower motor)

To control the motors, it requires motor drivers. In addition, the motor driver measures the motor current, and allows us to detect obstacles as motor current increases at obstacles. Ardumower uses two dual MC33926 motor drivers, so two channels for left and right motor and two dual channels (connected in parallel) for the mowing motor.

It is not safe to connect motors directly to the motor driver. Especially, when quickly turning motors from forward to reverse (or vice verse), high voltage spikes appear, and these could damage the motor drivers in the long run. Therefore, we developed driver protector boards that are connected between motor driver and motor.

Voltages

As in all modern systems, Ardumower uses 24V motors.

Motor driver assembly (dual MC33926)

Motor driver features: up to 3A with integrated current sensor and thermal shut-down protection

For wiring of motor drivers, protector and motors, please open manual in section Protector PCB.

Protector PCB

![]() When quickly tunring motors from forward to backward (or vice versa), high voltage spikes appear. These high voltage spikes could damage the motor driver in the long run. To eliminate high voltage spikes, it is adviced to use a Protector board between motor driver and motor. Two Protector PCBs are required, one for the gear motors, and one for the mowing motor.

When quickly tunring motors from forward to backward (or vice versa), high voltage spikes appear. These high voltage spikes could damage the motor driver in the long run. To eliminate high voltage spikes, it is adviced to use a Protector board between motor driver and motor. Two Protector PCBs are required, one for the gear motors, and one for the mowing motor.

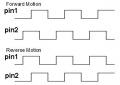

Wheel motors wiring

The two left and right gear motors are controlled independently (aka 'differential driving') to:

- drive the robot forward/backward

- steer the robot left/right

Wheel motor features:

- A rotation speed up to 31 rpm allows to move the robot at sufficient speed (at up to meter/sec = 31rpm/60 * PI * 0.25m = 0.4m/sec using 250mm diameter wheels)

- A high torque (2.45Nm) guarantees that the robot can climb small hills as well (with 2 motors, 0.125 radius wheel, 31rpm = 0.4m/s, acceleration = 0.2 ( 1/2 of nominal speed) see calculator

- Integrated encoders, so it can measure the rotation speed and the distance

- 24V (load current ~1A)

The left gear motor is connected as follows to the protector board:

Motor wiring (left motor):

Motor (black) ==== Protector board Motor_1_OUT(1) Motor (red) ==== Protector board Motor_1_OUT(2)

For right motor, use Protector board Motor_2_OUT(1,2) accordingly.

Wheel motors odometry wiring

The Ardumower gear motors have integrated encoders. These encoders help us to compute speed and traveled distance. Here's how you connect the motor odometry wires to the PCB.

Motor odometry wiring (left motor):

Motor (brown) ---- PCB VCC Motor (green) ---- PCB GND Motor (blue) ---- PCB OdometryLeft (3) Motor (purple) ---- PCB OdometryLeft (4)

For right motor, use PCB OdometryRight accordingly.

IMPORTANT: PCB v0.5/1.2 are missing pull-up resistors! You need to add them yourself at the PCB:

PCB OdometryLeft(3) --- 4.7k --- 5v PCB OdometryLeft(4) --- 4.7k --- 5v

Mower motor wiring

The Ardumower mower motor features:

- Fast enough to cut the lawn (3150 rpm)

- Enough torque (140 mNm / 46 W)

- Quiet mowing (you cannot hear it)

- 24V, load current ~1.0A (L=2.8mH, R=1.9ohm)

![]() Security note: For security reasons, always remove mower blades in your first tests!

Security note: For security reasons, always remove mower blades in your first tests!

Here's how you connect the mowing motor to the protector board:

Motor (black) ==== Protector board Motor_1_OUT(1) Motor (red) ==== Protector board Motor_1_OUT(2)

Motor decrease noise

Here's how you can decrease motor noise:

Motor controller (PID)

The speed of the motors is controlled by a software PID controller. You can monitor the quality of the motor speed control via pfodApp (Plot->Motor control):