Wheel Motor: Unterschied zwischen den Versionen

(→Motor controller (PID)) |

(→Motors testing) |

||

| (4 dazwischenliegende Versionen desselben Benutzers werden nicht angezeigt) | |||

| Zeile 19: | Zeile 19: | ||

= Wiring = | = Wiring = | ||

| − | One pin controls the direction (forward/backward) | + | Using motor driver MC33926 : |

| + | |||

| + | Right | Left | ||

| + | |||

| + | Pin 33 | Pin 31 One pin controls the direction (forward/backward) | ||

| + | |||

| + | Pin 03 | Pin 05 the other pin controls the speed. | ||

| + | |||

| + | Pin A0 | Pin A1 One analog input pin is connected to the current sensor. | ||

| + | |||

| + | Pin 27 | Pin 25 input pin to read fault | ||

<gallery> | <gallery> | ||

| − | File: | + | File:MC33926_schematics.jpg | schematics |

</gallery> | </gallery> | ||

| + | |||

[https://github.com/Ardumower/ardumower/raw/master/pcb/megashield_svn_1.2_geschlossen/Dokumentation/WORKSHOP%20Protector-Board.pdf Protector board] is adviced to be used between controler and motor. | [https://github.com/Ardumower/ardumower/raw/master/pcb/megashield_svn_1.2_geschlossen/Dokumentation/WORKSHOP%20Protector-Board.pdf Protector board] is adviced to be used between controler and motor. | ||

| + | |||

| + | == Alternative solution == | ||

| + | |||

| + | The current sensor module (ACS712-05A) is connected in series with the motor. | ||

| + | <gallery> | ||

| + | File:Ardumower_motor_driver_circuit.png | NOTE: only for demonstration! See real [http://wiki.ardumower.de/index.php?title=Ardumower_PCB schematics] for concrete wiring | ||

| + | </gallery> | ||

| + | |||

== Control principal : PWM frequency == | == Control principal : PWM frequency == | ||

| Zeile 48: | Zeile 67: | ||

= Programming = | = Programming = | ||

| − | == Motor | + | == Motor variables == |

// --------- wheel motor state ---------------------------- | // --------- wheel motor state ---------------------------- | ||

// wheel motor speed ( <0 backward, >0 forward); range -motorSpeedMaxRpm..motorSpeedMaxRpm | // wheel motor speed ( <0 backward, >0 forward); range -motorSpeedMaxRpm..motorSpeedMaxRpm | ||

| − | float motorAccel ; | + | // [Default value] |

| − | int motorSpeedMaxRpm ; | + | float motorAccel ; // motor wheel acceleration - only functional when odometry is not in use |

| − | int motorSpeedMaxPwm ; | + | // (warning: do not set too high) [1000] |

| − | float motorPowerMax ; | + | int motorSpeedMaxRpm ; // motor wheel max RPM [25] |

| − | PID motorLeftPID; | + | int motorSpeedMaxPwm ; // motor wheel max Pwm (8-bit PWM=255, 10-bit PWM=1023) [255] |

| − | PID motorRightPID; | + | float motorPowerMax ; // motor wheel max power (Watt) |

| + | PID motorLeftPID; // motor left wheel PID controller [Kp=1.5 , Kd=0.29, Ki=0.25] | ||

| + | PID motorRightPID; // motor right wheel PID controller | ||

float motorSenseRightScale ; // motor right sense scale (mA=(ADC-zero)/scale) | float motorSenseRightScale ; // motor right sense scale (mA=(ADC-zero)/scale) | ||

| − | float motorSenseLeftScale ; // motor left sense scale (mA=(ADC-zero)/scale) | + | float motorSenseLeftScale ; // motor left sense scale (mA=(ADC-zero)/scale) |

| − | int motorRollTimeMax ; | + | int motorRollTimeMax ; // max. roll time (ms) |

| − | int motorRollTimeMin ; // min. roll time (ms) | + | int motorRollTimeMin ; // min. roll time (ms) |

| − | int motorReverseTime ; | + | int motorReverseTime ; // max. reverse time (ms) |

| − | long motorForwTimeMax; // max. forward time (ms) / timeout | + | long motorForwTimeMax; // max. forward time (ms) / timeout |

| − | float motorBiDirSpeedRatio1 ; | + | float motorBiDirSpeedRatio1 ;// bidir mow pattern speed ratio 1 |

| − | float motorBiDirSpeedRatio2 ; | + | float motorBiDirSpeedRatio2 ;// bidir mow pattern speed ratio 2 |

| − | bool motorRightSwapDir ; | + | bool motorRightSwapDir ; // inverse right motor direction? |

| − | bool motorLeftSwapDir ; | + | bool motorLeftSwapDir ; // inverse left motor direction? |

| − | int motorLeftSpeedRpmSet ; // set speed | + | int motorLeftSpeedRpmSet ; // set speed |

int motorRightSpeedRpmSet ; | int motorRightSpeedRpmSet ; | ||

| − | float motorLeftPWMCurr ; // current speed | + | float motorLeftPWMCurr ; // current speed |

float motorRightPWMCurr ; | float motorRightPWMCurr ; | ||

int motorRightSenseADC ; | int motorRightSenseADC ; | ||

| Zeile 76: | Zeile 97: | ||

float motorLeftSenseCurrent ; | float motorLeftSenseCurrent ; | ||

float motorRightSenseCurrent ; | float motorRightSenseCurrent ; | ||

| − | float motorLeftSense ; | + | float motorLeftSense ; // motor power (range 0..MAX_MOTOR_POWER) |

float motorRightSense ; | float motorRightSense ; | ||

int motorPowerIgnoreTime; | int motorPowerIgnoreTime; | ||

| Zeile 88: | Zeile 109: | ||

boolean rotateLeft; | boolean rotateLeft; | ||

unsigned long nextTimeRotationChange; | unsigned long nextTimeRotationChange; | ||

| + | |||

| + | == Motor Methods == | ||

| + | |||

| + | First the basic function that control the pwm to each motors: | ||

| + | void setMotorPWM(int pwmLeft, int pwmRight, boolean useAccel); | ||

| + | |||

| + | A general methods to test motors | ||

| + | void testMotors(); | ||

| + | |||

| + | Then, there are several MotorControl methods according to mower state : | ||

| + | |||

| + | if current state is 'STATE_PERI_TRACK' then | ||

| + | void motorControlPerimeter(); | ||

| + | |||

| + | |||

| + | void motorControlImuRoll(); | ||

| + | |||

| + | void motorControlImuDir(); | ||

| + | |||

| + | for all other case : | ||

| + | |||

| + | void motorControl(); | ||

| + | // This method calculate pwm to set in order to respect rpm setpoint according current rpm and Kp, Ki, Kd parameter | ||

| + | |||

| + | = Motors testing = | ||

| + | |||

| + | Run the serial console (Arduino IDE: CTRL+SHIFT+M, 19200 Baud) and press 'd' and ENTER for menu. | ||

| + | Then press '1' and ENTER to run the motor test. | ||

| + | |||

| + | Test consist of the following sequence : | ||

| + | |||

| + | * Left motor : Forward half speed | ||

| + | |||

| + | * Left motor : Reverse full speed | ||

| + | |||

| + | * Right motor : Forward half speed | ||

| + | |||

| + | * Right motor : Reverse full speed | ||

| + | |||

| + | |||

| + | NB : If motor rotation is inverse to what is expected, then you need to switch the wiring at the outlet of motor controller. | ||

Aktuelle Version vom 2. Januar 2016, 13:17 Uhr

Inhaltsverzeichnis

Wheel motors caracteristics & driver

The two left and right gear motors are controlled independently (aka 'differential driving') to:

- drive the robot forward/backward

- steer the robot left/right

The Ardumower wheel motor features:

- A rotation speed up to 31 rpm allows to move the robot at sufficient speed (at up to meter/sec = 31rpm/60 * PI * 0.25m = 0.4m/sec using 250mm diameter wheels)

- A high torque (2.45Nm) guarantees that the robot can climb small hills as well (with 2 motors, 0.125 radius wheel, 31rpm = 0.4m/s, acceleration = 0.2 ( 1/2 of nomeinal speed) up to 14 degree) see calculator

- Integrated encoders, so it can measure the rotation speed, the distance and the direction (see Odometry for more information) - Encoders are REQUIRED for Ardumower software.

- 24V (load current ~1A)

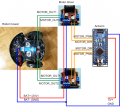

Wiring

Using motor driver MC33926 :

Right | Left

Pin 33 | Pin 31 One pin controls the direction (forward/backward)

Pin 03 | Pin 05 the other pin controls the speed.

Pin A0 | Pin A1 One analog input pin is connected to the current sensor.

Pin 27 | Pin 25 input pin to read fault

Protector board is adviced to be used between controler and motor.

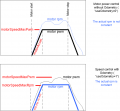

Alternative solution

The current sensor module (ACS712-05A) is connected in series with the motor.

NOTE: only for demonstration! See real schematics for concrete wiring

Control principal : PWM frequency

The speed of the motor is controlled by a PWM duty signal. We use the Arduino default PWM frequency (490 Hz) to control the motor drivers.

Motor controller (PID)

The speed of the motors is controlled by a software PID controller. You can monitor the quality of the motor speed control via pfodApp (Plot->Motor control):

Programming

Motor variables

// --------- wheel motor state ----------------------------

// wheel motor speed ( <0 backward, >0 forward); range -motorSpeedMaxRpm..motorSpeedMaxRpm

// [Default value]

float motorAccel ; // motor wheel acceleration - only functional when odometry is not in use

// (warning: do not set too high) [1000]

int motorSpeedMaxRpm ; // motor wheel max RPM [25]

int motorSpeedMaxPwm ; // motor wheel max Pwm (8-bit PWM=255, 10-bit PWM=1023) [255]

float motorPowerMax ; // motor wheel max power (Watt)

PID motorLeftPID; // motor left wheel PID controller [Kp=1.5 , Kd=0.29, Ki=0.25]

PID motorRightPID; // motor right wheel PID controller

float motorSenseRightScale ; // motor right sense scale (mA=(ADC-zero)/scale)

float motorSenseLeftScale ; // motor left sense scale (mA=(ADC-zero)/scale)

int motorRollTimeMax ; // max. roll time (ms)

int motorRollTimeMin ; // min. roll time (ms)

int motorReverseTime ; // max. reverse time (ms)

long motorForwTimeMax; // max. forward time (ms) / timeout

float motorBiDirSpeedRatio1 ;// bidir mow pattern speed ratio 1

float motorBiDirSpeedRatio2 ;// bidir mow pattern speed ratio 2

bool motorRightSwapDir ; // inverse right motor direction?

bool motorLeftSwapDir ; // inverse left motor direction?

int motorLeftSpeedRpmSet ; // set speed

int motorRightSpeedRpmSet ;

float motorLeftPWMCurr ; // current speed

float motorRightPWMCurr ;

int motorRightSenseADC ;

int motorLeftSenseADC ;

float motorLeftSenseCurrent ;

float motorRightSenseCurrent ;

float motorLeftSense ; // motor power (range 0..MAX_MOTOR_POWER)

float motorRightSense ;

int motorPowerIgnoreTime;

int motorZeroSettleTime; // how long (ms) to wait for motor to settle at zero speed

int motorLeftSenseCounter ; // motor current counter

int motorRightSenseCounter ;

unsigned long nextTimeMotorSense ;

unsigned long lastSetMotorSpeedTime;

unsigned long motorLeftZeroTimeout;

unsigned long motorRightZeroTimeout;

boolean rotateLeft;

unsigned long nextTimeRotationChange;

Motor Methods

First the basic function that control the pwm to each motors:

void setMotorPWM(int pwmLeft, int pwmRight, boolean useAccel);

A general methods to test motors

void testMotors();

Then, there are several MotorControl methods according to mower state :

if current state is 'STATE_PERI_TRACK' then

void motorControlPerimeter();

void motorControlImuRoll();

void motorControlImuDir();

for all other case :

void motorControl(); // This method calculate pwm to set in order to respect rpm setpoint according current rpm and Kp, Ki, Kd parameter

Motors testing

Run the serial console (Arduino IDE: CTRL+SHIFT+M, 19200 Baud) and press 'd' and ENTER for menu. Then press '1' and ENTER to run the motor test.

Test consist of the following sequence :

- Left motor : Forward half speed

- Left motor : Reverse full speed

- Right motor : Forward half speed

- Right motor : Reverse full speed

NB : If motor rotation is inverse to what is expected, then you need to switch the wiring at the outlet of motor controller.